Tensile Structure Uses and Advantages

July 27,2022

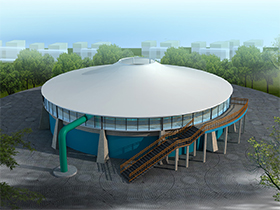

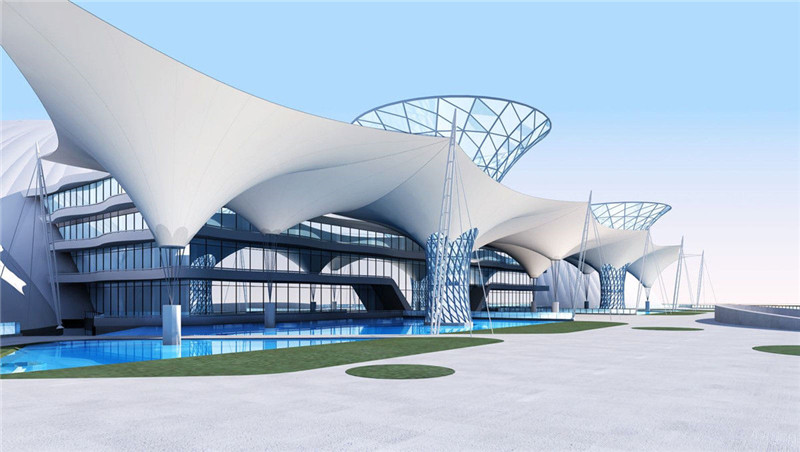

A tensile structure is a lightweight fabric structure that carries loads by utilizing tension. Stretch Structures Fabric Structures describe various stretch film structures and the current state of knowledge. Tensile fabric structures are commonly used in transportation facilities, buildings, and other applications that require a high degree of sustainability and aesthetics. They can also be used as a lightweight alternative to steel frames, such as skyscrapers, playground shade structures, garden shade structure, etc.

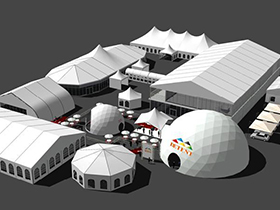

The design of tensile structures can vary depending on the needs of a specific project. They are often used to provide shade or shade to buildings. The beauty of tensile structures makes them an attractive option for many types of facilities. They also offer a unique combination of reliable functionality and aesthetic appeal. These benefits make them very popular structural systems. Some examples of tensile structures are listed below.Tensile structures can be designed with large or small areas. It can cover large spaces such as event venues, stadiums, performance venues or military structures. Smaller examples include outdoor restaurants, rooftop bars, tension shade sails, and more. Tensile construction is an excellent choice for outdoor applications because it gives an outdoor feel and is weather resistant.Due to its unique membrane tension properties, the tensile fabric structure has a uniquely elegant form. Its translucency also provides soft, diffused natural light. Artificial lighting can also be used to generate external lighting. Tensile structures can be used to create prefabricated modular buildings or as lightweight elements of existing structures. They are one of the most cost-effective options on the market. When properly designed and constructed, tensile fabric structures can be very durable.

.jpg)

German architect Frei Otto was a seminal figure in the development of tensile architecture. Frei Otto's pioneering work demonstrates that the relationship between architectural and structural form is intimate and mutually beneficial. Frei Otto's monumental tensile building, the Hangende Dach in Munich, won the 2015 Pritzker Architecture Prize. It redefines structures and prefabricated systems and shows that they are compatible with sustainable design.Stretch fabrics are typically combinations of fibers used in various applications. Tensile structure details have many advantages, including the ability to minimize the surface area between the dots. Plus, it's very efficient and maximizes the use of expensive, high-strength fibers. And because it's light, it's also durable. If you are looking for tensile structures for your project, please contact us today!

Tension structures are more cost-effective and use less material than tension fabric buildings. Tensile structures can create entire buildings, making them the first choice for complex design work. tensile fabric structures are typically made of thin fabrics that are pulled in opposite directions to create a double curvature. The double curvature doubles the stiffness of the fabric. Tensile structures can span great distances without intermediate supports.

What is Tension Structure & What are its Benefits

July 13,2022

.jpg)

The basic concept behind tensile structures is the use of fabrics to create strong structural systems. These structures can be reinforced with high-strength cables at a much lower cost than traditional steel or concrete structures. While some fabric structures rely on mechanical devices to keep their structures in place, their reliance on these devices can lead to troubling deflation and other problems. The increasing acceptance of fabric structures makes tensile fabric structures a less controversial structural system.

While tensile architecture is better known today, its roots can be traced back to the Ice Age. The Siberian steppe is home to primitive human settlements made of animal skins draped between wooden sticks. This may be the first tensile structure because it is lightweight and easy to transport. Eventually, humans will develop ways to replicate these structures using more efficient and sustainable materials. Today, the process is widely used in large buildings. Tensile buildings can be used as general storage or waste management facilities. However, tensile buildings cannot be designed to include windows or support a solid roof. However, this does not limit design options. Instead, the steel frame of the structure can be adjusted to create dramatic shapes. Fabric can also be manipulated for interesting visual effects. This allows for a wider variety of applications than conventional construction.

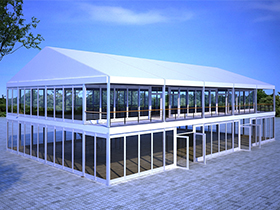

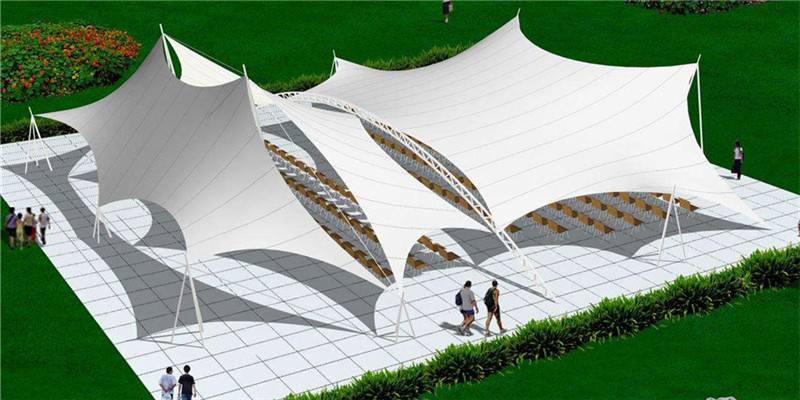

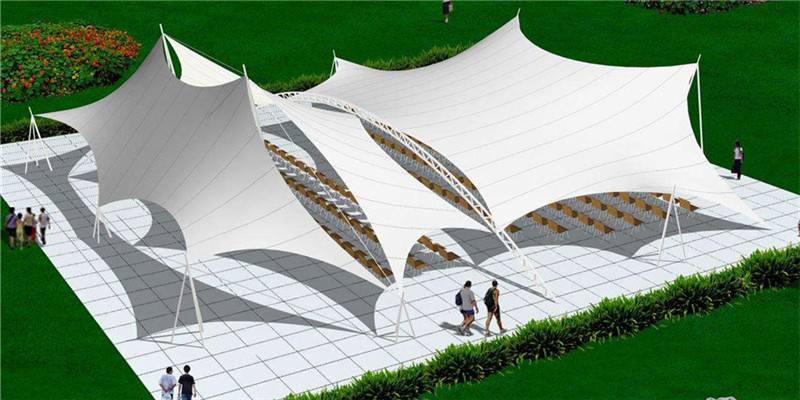

Another name for tension structures is tension fabric structures. retractable pergola shade cloth Tension fabric buildings are lightweight structure, easy to install, and can span great distances without the need for internal columns or poles. Tension fabric buildings typically include a steel frame for structural support, and the fabric acts as a protective covering that lets in natural light and protects from the elements. While this construction has the advantage of being able to span great distances, the fabric has little room for folds and is still durable. Now many scenic spots will have buildings that can also be used as permanent gazebo structures. The style is changeable and it is also an iconic building. In addition to being aesthetically pleasing, stretch fabric construction is also a very economical option. Tensile structures are easier to build and less expensive to maintain than traditional steel or concrete structures. Tensile fabric structures can be used in many different applications, from existing buildings to freestanding structures. Its unique geometry makes it one of the most versatile and affordable structures on the market.

Another benefit of the types of tensile structure is that it is highly reflective. It provides more efficient lighting at night and significantly reduces demands on the HVAC system. Additionally, the highly reflective surface of the stretch fabric makes it ideal for shading façades and ceiling planes. The benefits of this structure are countless. You can use it as a facade for buildings, parking lots or sports fields.The basic components of a stretch fabric construction are the saddle and the cone. These are asymmetrical forms that can be combined to meet specific needs. By combining these two components, the tension structure can achieve any desired shape. This type of structure is called prestressing and can be used in a variety of applications. If you are looking for a simple yet versatile tensile structure, a bulletproof saddle will serve you well.

What are the Advantages of Tensile Fabric Structures Over Traditional Buildings?

July 05,2022

A tension fabric structure is a building that uses fabric as a structure to support weight. Often called tensile façades, these structures can be used to cover the exterior of buildings, car parks or sports fields. The stretch construction is also great for incorporating brand messages into fabric graphics. Here's a closer look at the benefits of stretch fabric construction.

tension fabric structures uses two basic building blocks: saddle and cone. Both shapes are very versatile and can be used to create structures that suit your requirements. The saddle can be thought of as a twisted grid of rectangles, while the cone is more like a volcano. Two types of fabric tension structures can be stacked to create efficient designs. What's more, the stretch fabric construction can last 45 years!

Frei Otto was an early pioneer of tensile construction. Frei Otto discovered that many natural forms have perfect tension and developed a method to connect them. He later developed a model with soap. The process of developing this architectural model has led to numerous innovations in tensile architecture. In the years that followed, more and more architects and designers began to incorporate tensile structures into their work.

Tensile structures are a good alternative to traditional buildings. As the name suggests, they consist of a metal frame and fabric shell. Compared to traditional buildings, tensile structures use less material and are more environmentally friendly. Steel is an excellent skeleton material and requires less material for the structure than conventional construction. In 2014, a steel framed tensile building was able to withstand 130 mph winds!

The earliest tensile structures were used for portable outer shelters, such as tents, shelters. Since then, they have continued to evolve as different people used different materials, climates and architectural styles. Bedouins and Berbers use black tents, while Moors and Kurds use tent-like structures for shelter. So what are the advantages of tensioned structures over traditional buildings?

The tension fabric structure has a highly reflective surface for better lighting even during the day. This results in a significant reduction in the energy required for lighting and HVAC systems. This means lower utility bills for homeowners. The highly reflective surface of the tensile structure is a great advantage for energy efficient buildings! This makes it perfect for buildings and parks. If you plan to place tensile structures on your property, consider the following benefits:

Tensile structures use less material than tensile fabric buildings, and it can be used to construct entire buildings. It is easier to install and requires fewer internal struts than tension fabric construction. Tension fabric buildings typically use a steel frame as structural support and fabric as a protective layer to keep out the elements. You get all the benefits of tension structures without the high cost of interior construction.

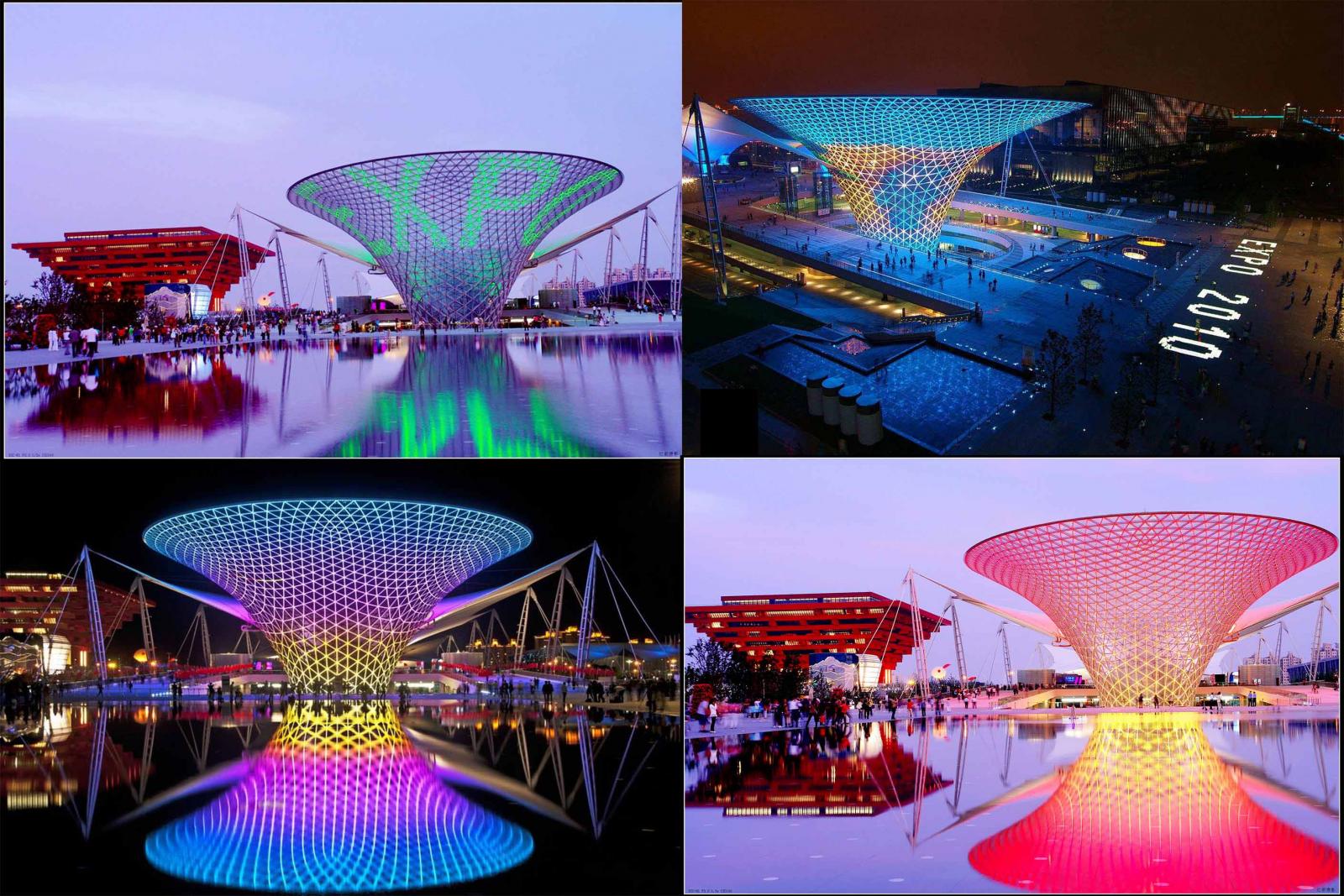

Sunshine Valley & China is First Cable Membrane Structure

June 16,2022

China's first cable membrane structure, Sunshine Valley, is located at the Expo source in the core area of Shanghai World Expo Park. "Aorta".Speaking of the 6 giant "Sunshine Valleys", "it is composed of 13 large masts, dozens of cables and huge membrane fabrics. It is definitely the first cable-membrane structure building in China and rare in the world." 6 "Sunshine Valleys" ”, the largest of which is 97 meters in diameter, and the lower one is 20 meters in diameter, so that the underground pedestrian walkway of the 1000-meter Expo axis borrows natural light. The special structure composed of huge masts and stay cables is natural with the giant white membrane cloth.

The 250-kilometer-long pipeline is warm in winter and cool in summer. The Expo Axis is also an "experimental field" for Shanghai's circular economy. Xu Jun, Executive Manager of the Expo Axis Project, said that a 250-kilometer-long pipeline was laid under the Expo Axis to form a ground source heat pump, which was introduced into Huangpu. river water. In summer, filtered river water is used to form a cooling system, and in winter, a heating system with ground source heat as the main source and Huangpu River water as a supplement is used, so that this huge public channel uses natural resources to achieve warmth in winter and cool in summer.

The basic construction of Sunshine Valley uses square steel pipes instead of round pipes. Several square pipes meet at the same point, which are called "nodes". The mesh shape of the appearance of Sunshine Valley is connected by "nodes" of different sizes. And each Sunshine Valley has about 3,000 "nodes", which can be calculated but cannot be drawn on the drawings. The membrane structure on the top adopts the highest strength membrane material in the world, and its design tension is 5 tons per meter. Since there are no pillars on the Expo axis platform, the membrane material relies on 31 outer masts, 19 inner masts and 817 inner masts. Wire rope to pull, and to pull evenly. At the same time, due to the different sizes and shapes of the Sunshine Valley, the node positions of the cables are also different, which brings about changes in the orientation and angle of the cables, which need to be solved one by one during the construction.

As the largest single building in the "one axis and four halls" permanent buildings in the Expo site, the Expo axis project has been transferred from the main structure construction to the decoration construction stage, and the cables and lamps for landscape lighting have been arranged outside the steel structure of the Sunshine Valley. The Expo Axis and Sunshine Valley at night will be more exciting.

What is the Difference Between a Fabric Tensioned Membrane Structure Carport and a Traditional Carport

June 28,2022

In practical applications, the membrane structure charging pile carport can not only protect the charging pile, but also protect the vehicles under the membrane structure charging pile carport. It not only has a waterproof sunshade structure in the sun and rain and snow. As a new type of charging pile carport, the membrane structure charging pile carport not only brings a lot of convenience to our travel, but also compared with the traditional carport, it is not only simple in construction, but also very beautiful in appearance, stretching The structural strength of the building materials used in the membrane structure is also very high, which can not only shield the charging piles and vehicles from wind and rain, but also add a beautiful color to the city due to its aesthetics. Membrane structure, also known as fabric structure, is widely used not only in commercial buildings, transportation facilities, sports fields, gymnasiums and other places.

Artistic: membrane structure modeling and color Relying, it can combine natural conditions and ethnic customs, and create curve shapes that are difficult to achieve in traditional buildings according to the architect's creativity. Membrane structure is an architect's romantic vision, enjoying a romantic space like nature.

Economy: The fabric structure has a certain light transmittance, which can reduce the lighting intensity and time during the day, and can save energy well, which also makes the membrane structure a very environmentally friendly building.

Large-span: The tensile structure can fundamentally overcome the difficulties encountered by traditional structures in the realization of large-span (unsupported) buildings, create a huge unobstructed visual space, and effectively increase the space usable area.

Self-cleaning: Steel building materials use membranes with protective coatings, which can make buildings have a good self-cleaning effect and ensure their service life.

Short construction period: Due to the particularity of the fabric tension structure, their construction period is greatly shortened compared with ordinary buildings, which improves the work efficiency

Fabric structure canopy of pedestrian bridge - a beautiful landscape in the city

May 19,2022

With the increase of urban population and traffic flow, in densely populated areas such as schools, hospitals, commercial plazas and residential quarters, there is a large demand for pedestrians to cross the street, which usually conflicts with the normal passage of vehicles and poses potential safety hazards. As a result, overpasses across the street were erected, improving the efficiency of vehicle traffic and ensuring the safety of pedestrians crossing the street.

In people's impressions, the overpasses across the street are steel bridges with guardrails, and the more beautiful ones are the circular overpasses at the crossroads. However, with the rapid development of ETFE, PTFE, PVDF membrane materials and stainless steel and aluminum alloy materials, the advantages of membrane structures have been fully utilized in the design and construction of overpasses, making overpasses no longer a cold cross-street building with a traffic function, but also a Landscape bridges and viewing bridges add to the city's temperature and style.

Due to its special shape and the performance of the membrane material itself, the membrane structure can create design ideas that cannot be achieved by traditional building systems.

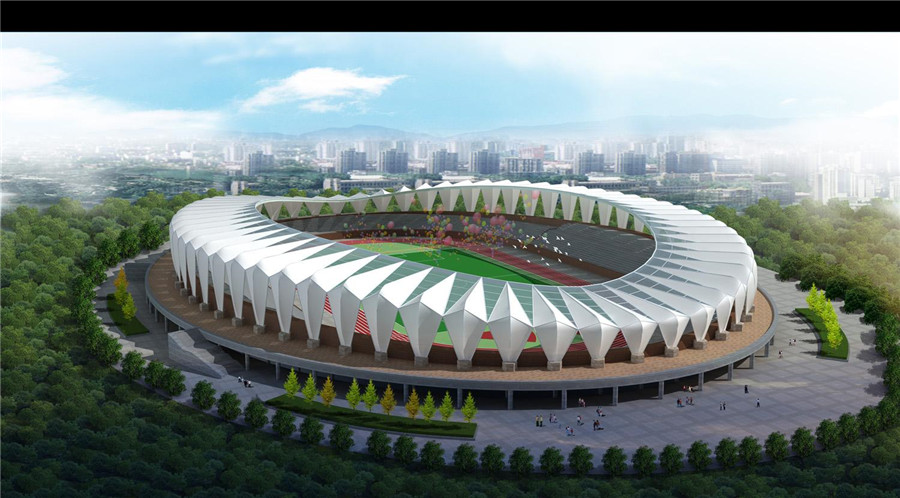

Why do stadium stands use membrane & fabric structure?

May 09,2022

1. Membrane structure is a new type of material, which is artistic, economical, thermal insulation, self-cleaning, fireproof, sound-absorbing and light-transmitting. The use of membrane structure in sports stands can better reflect this feature of membrane structure. Compared with traditional stands, the membrane structure of sports stands has the characteristics of beautiful shape, large space span, light weight and long service life. Membrane structure is a new form of building structure, which integrates architecture, structural mechanics, fine chemical and material science, computer technology, etc., and has a high technical content. Its curved surface can be arbitrarily changed according to the architect's design needs, combined with the overall environment, to build an iconic image project. The stand membrane structure membrane material is made of polyester fiber base cloth or different surface coatings such as PVDF, PVF, PTFE, etc., together with high-quality PVC, which has a stable shape and can bear a certain load of architectural textiles. Its life varies with different surface coatings, generally reaching 15-30 years.

2. The stands of the stadium with membrane structure are beautiful in appearance and large in space span. It better reflects the advantages of the space span of the membrane structure building, and the construction period is short. The characteristics of membrane structures have attracted more and more attention, and because of this, more and more membrane structures are designed to use membrane structures to replace traditional concrete buildings. The weight of membrane building roof is only 1/30 of that of conventional steel roof, which reduces the cost of wall and foundation. At the same time, the peculiar shape and night scene effect of the membrane building have obvious "architectural visibility" and commercial effect, and its price-effectiveness ratio is higher.

3. The beautifully shaped membrane material, stainless steel fittings and fasteners plus the light and reasonable design and strict surface treatment of the steel structure support, create a membrane structure with beautiful form and reasonable design, which occupies an important place in the architectural environment design around the world today. important position.

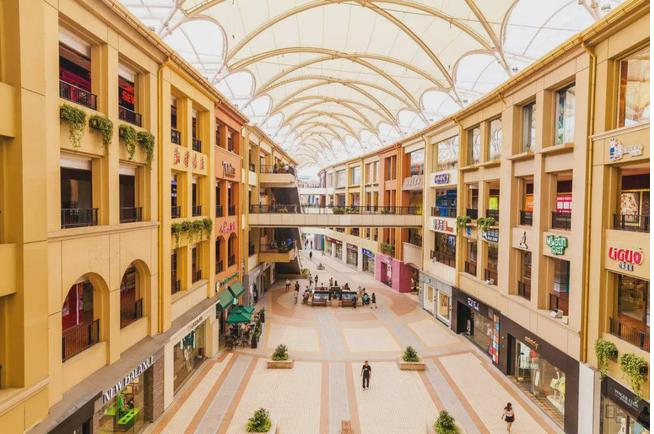

Why did shopping mall Dome & Skylight choose fabric structure?

April 27,2022

The main feature of the commercial shopping center is that the concentration of commercial stores forms indoor and outdoor shopping, leisure, dining and other functional spaces. The pedestrian street and the central activity area are open spaces for people to walk, rest and communicate. Based on the characteristics of the commercial street, it is determined The core of all designs is to make the space more human.

As an additional facility of the building, the roof not only requires the practical function of shading and rain protection, but also should be the icing on the cake. At present, there are more and more engineering cases where fabric membrane structures are used in commercial complexes. The roofs built with membrane structures have many advantages that traditional roofs do not have.

Membrane structure buildings are very popular in commercial applications. The detachability and large span of the membrane structure are suitable for building a commercial exhibition area. Now many shopping malls have used the outer top layer of the membrane structure single room, which will be unique compared to the traditional structure.

The emergence of the membrane structure solves various drawbacks of traditional materials. PTFE and ETFE membranes can not only achieve light transmittance, but also lightweight and higher safety. In particular, ETFE membranes can achieve 95%-100% light transmittance, such as It is as transparent as glass, no additional lighting is required during the day, and it greatly saves energy consumption. Therefore, it has been adopted by many architects and has become the first choice for large-scale commercial blocks.

Why choose fabric for the façade?

April 25,2022

"Fabric Curtain Wall & facade" is a building facade solution that uses weather-resistant flexible fabric materials, combined with frame systems, to renovate the facades of existing buildings or design the facades of new buildings. This material can make the building with a large volume present a light and transparent visual sense. It is divided into metal fabric curtain wall and flexible material non-metal fabric curtain wall. Its curved surface can be arbitrarily changed according to the architect's design needs, combined with the overall environment, to build an iconic image project.

Application of fabric materials and three major advantages: light dyeing, printing and printing, and arbitrary modeling.

01. Lighting Dyeing - Use light to change the color of the façade arbitrarily, and the fabric façade changes the atmosphere with the indoor light, so that the building is no longer a static face. Plus, the soft fabric achieves a hard metallic feel.

02. Printing and inkjet printing - on the basis of perfect metal texture, you can print any pattern you want. The printability of the mesh film surface provides a creative space for designers to enrich the shape of the building's façade and highlight the landmark image. The spray-painted pattern does not affect the transparency of the line of sight.

.jpg)

03. Arbitrary shape - Membrane material is used as the application project of building facade, which is a project using cable support and special aluminum profile tensioning curtain material. Using the softness and elasticity of materials, the 3-dimensional space develops, and the shape of the building presents a variety of shapes, especially suitable for various curved buildings that are difficult to achieve with other materials.

Custom & Design Fabric Tensile Structures | Outdoor Sun Umbrellas | Custom Sunshades

March 17,2022

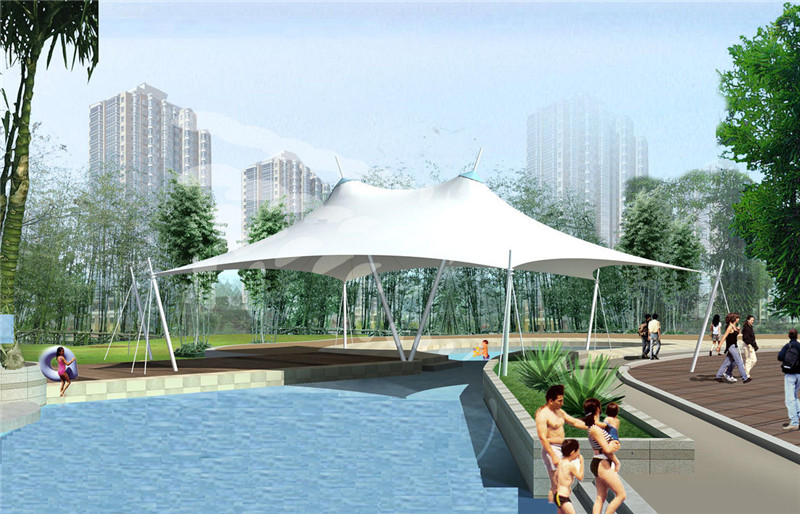

In a well-lit outdoor space, the shade of a shading structure is often indispensable, but the tensile structure is not only the function of shading, but also an important element in outdoor design. A sunshade that matches the environment can not only condense the overall atmosphere of the outdoor space, but also outline the pleasant outdoor scenery.

The fabric shade structures of outdoor structures can bring us visual unity and harmony, and can also plan the upper and lower priority in the space, creating a "focus". Whether opened or closed, an umbrella is a landscape.

Today's fabric structure design has become a fashion. Sunshades with different shapes and postures create a variety of styles for outdoor spaces. Or simple and modern, or relaxed and casual, or stable and elegant, or retro mix and match, an umbrella can emphasize the personality of the outdoor space.

The fabric structure and design should be self-contained with the decoration of the outdoor space, and should be in harmony with the surrounding natural environment. It is a marker of the human habitat, and at the same time a beautiful ornament in nature.

The fabric tent structures have the function of shading, so they naturally bring people a feeling of "safety and stability". In the open outdoors, with the existence of the fabric tension system, the whole space has more "home" atmosphere, making people more relaxed and comfortable.

For outdoor spaces, the shading structure is not only used during the day, but also provides lighting at night. Different lighting decorations also make the umbrellas glow with a different romantic atmosphere.

Archives

News at BDiR

How to Customize Your Own Glamping Tent

July 29,2022

Tensile Structure Uses and Advantages

July 27,2022

Geodesic Dome Tents Suitable for Living and all Types of Activities

July 22,2022

Watch Our Videos

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel

Luxury Sustainable Hospitality Eco Tent Structure Villas