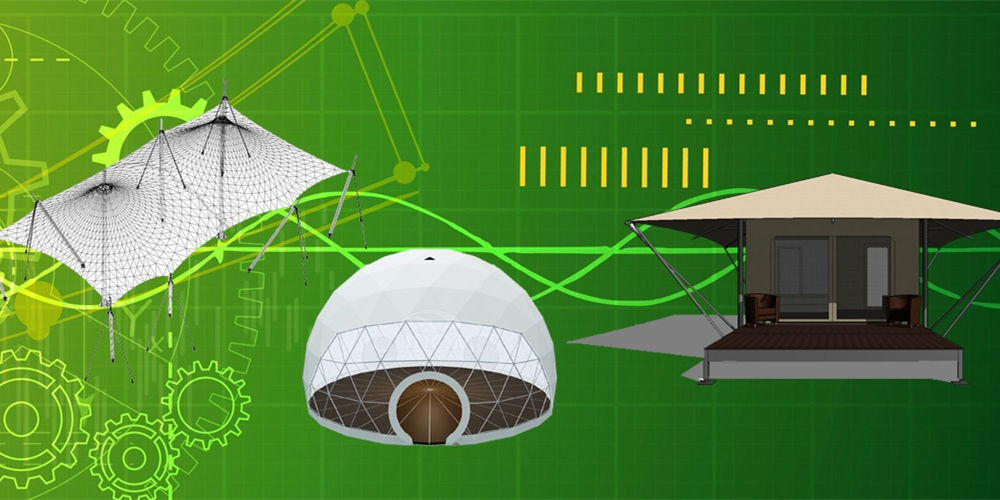

Tensile Membrane Structure Design & Manufacturer

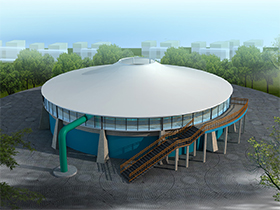

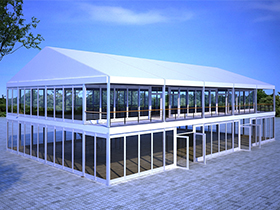

With 10 years of experience in the tensile membrane structures industry, we have successfully designed, engineered, manufactured and installed thousands of high quality tension membrane construction projects in 37 countries around the world. The tensile fabric structures used as roofing/canopy/shade/sail/marquee for sports facilities, transportation facilities, cultural facilities, landscape facilities, commercial facilities, sewage treatment canopy, biogas storage tanks, Air membranes structures, membrane structure hotels, Geodesic Domes etc. Our structure complies with local and international wind and snow load standards. We will never take risks when we provide our customers with a tensioned membrane structure that meets the wind and snow load requirements of each region or country.

-

Professional Manufacturer

We specialize in providing a full range of services from concept design to fabric structure project implementation.

-

Quality Service

We provide fast, high quality and enthusiastic service, and customer satisfaction is our number one priority.

-

Corporate Vision

Quality is the lifeline of our company. We have 0 fault tensile structure in our projects over the past 10 years.

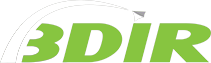

Steel Processing Factory

The steel structure processing factory covers an area of 3,000 m2. It has a CNC intersecting wire cutting machine, pipe bending machine beveling machines and a finishing workshop with turning, milling, planing and drilling. The annual steel structure processing capacity is 10,000 tons. It has the qualification of three-level construction of steel structure issued by the competent department of construction of the state.

Fabric Factory

The fabric membrane processing factory covers an area of 5,000 m2, with an annual production capacity of 200,000 m2 of PTEF; an annual production capacity of 100,000 m2 of ETFE; and an annual production capacity of 300,000 m2 of PVC / PVDF. We have the qualification of membrane structure design and construction issued by industry associations.

How to Customize Your Own Glamping Tent

Glamping tents are available in a variety of styles, perfect for your next family vacation. Choose from beautiful, custom-designed tents or demos. Many luxury tents feature an on-site spa, full 5' sidewalls and steel D-rings at the eaves. Having 6+ foot sidewalls gives you more headroom and usable tent space.

Glamping, also known as glamping, is a great way to escape our busy lives. Glamping is the perfect place to get away from technology and enjoy nature, fresh air and absolute relaxation. Whether you prefer glamping with comfy beds, a unique style tent, or something completely off the beaten track, glamping offers the perfect experience. Luxury canvas camping tents can be purchased online or by finding a local dealer in your area. Choose from a variety of styles and sizes to find the perfect glamping tent for your family. Depending on size and style, you can choose from standard tents with single or double beds, or large luxury tents with three bedrooms. Multiple people can also stay in tent resorts together.

Luxury tents can be customized to suit your family's needs. Some are designed to accommodate up to 20 people, making them ideal for larger groups. Custom designed models feature standing height ceilings and lots of floor space. Some even have integrated mesh windows. This means that no two people will have to crowd. With so many options, finding the perfect glamping tent isn't difficult. If you think the cost is too high, you can also idle time and tents for sale. It is also a way to get money back. Tent rental prices vary by the degree of luxury tent you customize

Camping tents are an elegant way to spend an unforgettable vacation. These accommodations feature modern conveniences and can be equipped with Wi-Fi, air conditioning, custom decks and flush toilets. If you want something stylish and practical for the whole family, consider buying a dome-shaped glamping tent. A luxury tent will be your best value for money. If you have an for a camping tent ideas, choose BDIR.

Tensile Structure Uses and Advantages

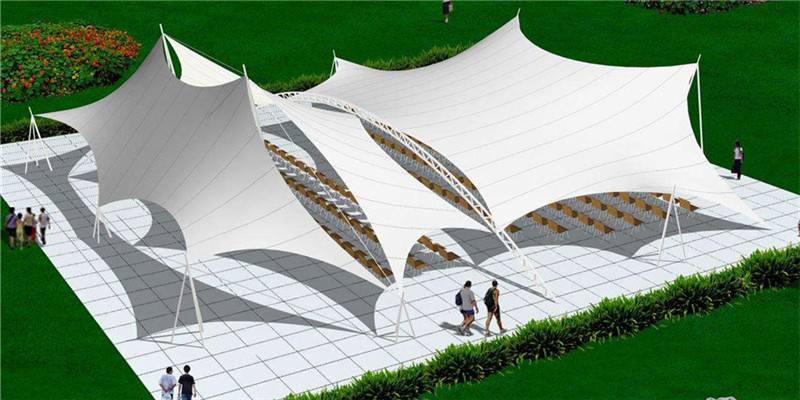

A tensile structure is a lightweight fabric structure that carries loads by utilizing tension. Stretch Structures Fabric Structures describe various stretch film structures and the current state of knowledge. Tensile fabric structures are commonly used in transportation facilities, buildings, and other applications that require a high degree of sustainability and aesthetics. They can also be used as a lightweight alternative to steel frames, such as skyscrapers, playground shade structures, garden shade structure, etc.

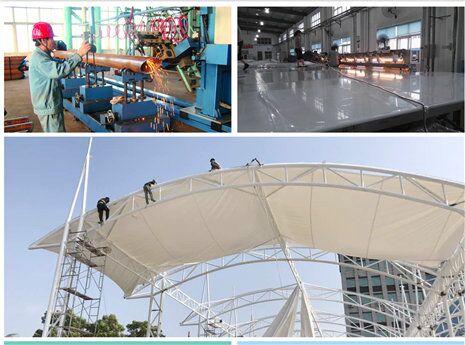

The design of tensile structures can vary depending on the needs of a specific project. They are often used to provide shade or shade to buildings. The beauty of tensile structures makes them an attractive option for many types of facilities. They also offer a unique combination of reliable functionality and aesthetic appeal. These benefits make them very popular structural systems. Some examples of tensile structures are listed below.Tensile structures can be designed with large or small areas. It can cover large spaces such as event venues, stadiums, performance venues or military structures. Smaller examples include outdoor restaurants, rooftop bars, tension shade sails, and more. Tensile construction is an excellent choice for outdoor applications because it gives an outdoor feel and is weather resistant.Due to its unique membrane tension properties, the tensile fabric structure has a uniquely elegant form. Its translucency also provides soft, diffused natural light. Artificial lighting can also be used to generate external lighting. Tensile structures can be used to create prefabricated modular buildings or as lightweight elements of existing structures. They are one of the most cost-effective options on the market. When properly designed and constructed, tensile fabric structures can be very durable.

.jpg)

German architect Frei Otto was a seminal figure in the development of tensile architecture. Frei Otto's pioneering work demonstrates that the relationship between architectural and structural form is intimate and mutually beneficial. Frei Otto's monumental tensile building, the Hangende Dach in Munich, won the 2015 Pritzker Architecture Prize. It redefines structures and prefabricated systems and shows that they are compatible with sustainable design.Stretch fabrics are typically combinations of fibers used in various applications. Tensile structure details have many advantages, including the ability to minimize the surface area between the dots. Plus, it's very efficient and maximizes the use of expensive, high-strength fibers. And because it's light, it's also durable. If you are looking for tensile structures for your project, please contact us today!

Tension structures are more cost-effective and use less material than tension fabric buildings. Tensile structures can create entire buildings, making them the first choice for complex design work. tensile fabric structures are typically made of thin fabrics that are pulled in opposite directions to create a double curvature. The double curvature doubles the stiffness of the fabric. Tensile structures can span great distances without intermediate supports.

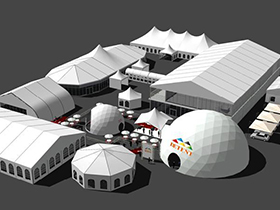

Geodesic Dome Tents Suitable for Living and all Types of Activities

Geodesic domes have become popular venues for events. They are perfect for a variety of uses including exhibitions, wedding banquet halls, press product launches, makeshift classrooms, ice rinks, and even swimming pool tent. You can even build one yourself with the right materials and easy-to-follow instructions. If you're not sure where to start, bdir can send you engineers and project managers to help you build your own geodesic dome.

Canvas dome tents can be used with any type of tent structure. Because it has no columns or load-bearing elements, it can be set almost anywhere without building permits. It can even be installed on concrete. Due to their strength and lightweight, tall dome tents are ideal for a variety of activities. Choosing the right tent structure for your needs is critical to a successful event.

Fuller's Geodesic Dome is in the spotlight after its Italian premiere. The domes were hugely popular at the 1954 Triennial, and the U.S. military was interested in using them for future projects, especially since they needed to provide solid housing for soldiers overseas. After winning the Gran Premio at the 1954 Triennial, Fuller's design gained wider public appeal. Another important advantage of a geodesic dome is its simplicity. The design allows for innovative interior and storage options. While geodesic domes are considered a luxury, they don't cost a fortune to build. Even if you don't have the budget for a permanent structure, you can easily transport it and set it up quickly anywhere. Pop-up events are a great place to place a geodesic dome. Other uses include ballrooms, planetariums, schools, conservatories, playgrounds, and even outdoor amphitheaters.

A geodesic dome is a hemispherical thin-shell structure based on a geodesic polyhedron. These are sturdy and lightweight, and they can hold a lot of weight compared to their size. The Missouri Botanical Garden used one of these to build a greenhouse in the 1960s. If you're looking for a unique country retreat, you should consider renting a dome tent. Not only are these tents durable and eco-friendly, but they are also very affordable. Plus, they can add a new dimension to your glamping experience. This unique style makes it a popular choice for every occasion, from family vacations to romantic getaways with your partner.