Ontwerp en Fabrikant van de Professionele Trekmembraanstructuur

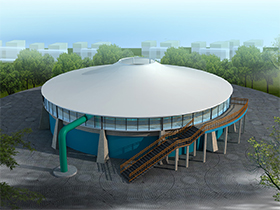

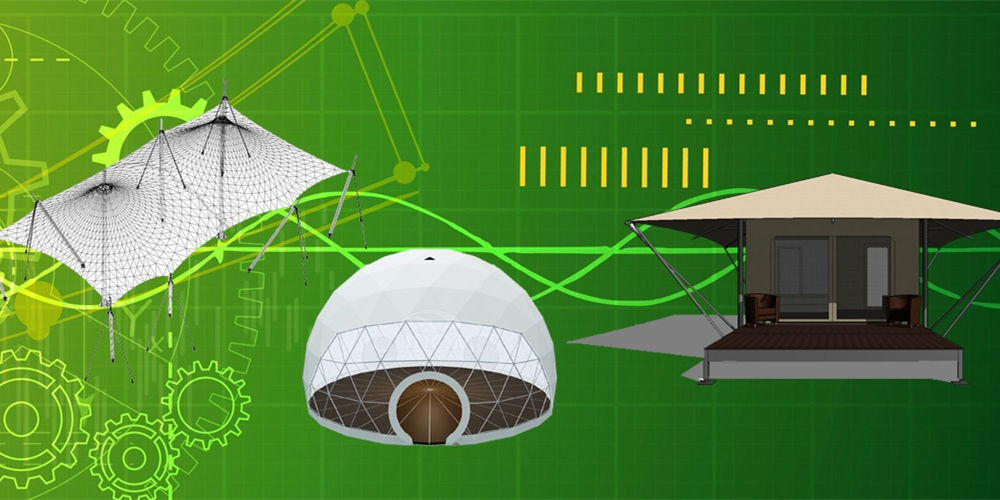

Met 10 jaar ervaring in de industrie van trekmembraanstructuren, hebben we met succes duizenden hoogwaardige spanningsmembraanbouwprojecten ontworpen, gebouwd, gebouwd en geïnstalleerd in 37 landen over de hele wereld. De trekstofstructuren die worden gebruikt als dakbedekking / luifel / schaduw / zeil / tent voor sportfaciliteiten, transportfaciliteiten, culturele voorzieningen, landschapsfaciliteiten, commerciële voorzieningen, rioolwaterzuiveringsinstallaties, biogasopslagtanks, luchtmembraanstructuren, membraanstructuurhotels, geodetische koepels, enz. Onze structuur voldoet aan de lokale en internationale normen voor wind- en sneeuwbelasting. We zullen nooit risico's nemen wanneer we onze klanten een gespannen membraanstructuur bieden die voldoet aan de wind- en sneeuwbelastingvereisten van elke regio of land.

-

Professionele fabrikant

Wij zijn gespecialiseerd in het leveren van een volledig scala aan services, van conceptontwerp tot en met de implementatie van een structuurstructuurproject.

-

Kwaliteitsservice

We bieden snelle, hoogwaardige en enthousiaste service en klanttevredenheid is onze belangrijkste prioriteit.

-

Bedrijfsvisie

Kwaliteit is de levensader van ons bedrijf. We hebben 0 breuktrekstructuur in onze projecten in de afgelopen 10 jaar.

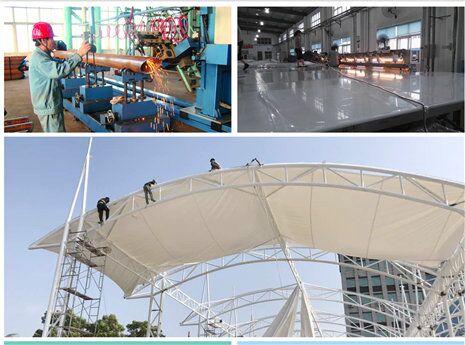

Staalverwerkende Fabriek

De fabriek voor de verwerking van staalconstructies heeft een oppervlakte van 3.000 m2. Het heeft een CNC-snijmachine voor draadsnijden, afschuinmachines voor pijpbuigmachines en een afwerkingsworkshop met draaien, frezen, schaven en boren. De jaarlijkse verwerkingscapaciteit van de staalstructuur is 10.000 ton. Het heeft de kwalificatie van drie-niveau constructie van staalconstructie uitgegeven door de bevoegde afdeling van de bouw van de staat.

Stoffen Fabriek

De fabriek voor de verwerking van weefselmembranen heeft een oppervlakte van 5.000 m2, met een jaarlijkse productiecapaciteit van 200.000 m2 PTEF; een jaarlijkse productiecapaciteit van 100.000 m2 ETFE; en een jaarlijkse productiecapaciteit van 300.000 m2 PVC / PVDF. We hebben de kwalificatie van membraanstructuurontwerp en constructie ction uitgegeven door brancheorganisaties.

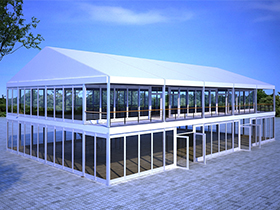

Hoe u uw Eigen Glamping-Tent Kunt Aanpassen

Glamping-tenten zijn verkrijgbaar in verschillende stijlen, perfect voor uw volgende familievakantie. Kies uit prachtige, op maat gemaakte tenten of demo's. Veel luxe tenten hebben een eigen spa, volledige 5 'zijwanden en stalen D-ringen aan de dakrand. Met zijwanden van meer dan 6 voet heeft u meer hoofdruimte en bruikbare tentruimte.

Glamping, ook wel glamping genoemd, is een geweldige manier om te ontsnappen aan ons drukke leven. Glamping is de perfecte plek om even weg te zijn van technologie en te genieten van de natuur, frisse lucht en absolute ontspanning. Of je nu de voorkeur geeft aan glamping met comfortabele bedden, een tent in unieke stijl of iets helemaal buiten de gebaande paden, glamping biedt de perfecte ervaring. Luxe canvas kampeertenten kunnen online worden gekocht of door een lokale dealer bij u in de buurt te zoeken. Kies uit verschillende stijlen en maten om de perfecte glampingtent voor uw gezin te vinden. Afhankelijk van grootte en stijl kun je kiezen uit standaard tenten met enkele of dubbele bedden, of grote luxe tenten met drie slaapkamers. Meerdere personen kunnen ook samen in tentenresorts verblijven.

Luxe tenten kunnen worden aangepast aan de behoeften van uw gezin. Sommige zijn ontworpen voor maximaal 20 personen, waardoor ze ideaal zijn voor grotere groepen. Op maat ontworpen modellen hebben plafonds op stahoogte en veel vloeroppervlak. Sommige hebben zelfs geïntegreerde gaasvensters. Dit betekent dat er geen twee mensen hoeven te verdringen. Met zoveel opties is het vinden van de perfecte glampingtent niet moeilijk. Als u de kosten te hoog vindt, kunt u ook vrije tijd en tenten te koop aanbieden. Het is ook een manier om geld terug te krijgen. Tenthuurprijzen variëren afhankelijk van de mate van luxe tent die u aanpast

Kampeertenten zijn een elegante manier om een onvergetelijke vakantie door te brengen. Deze accommodaties beschikken over moderne gemakken en kunnen worden uitgerust met Wi-Fi, airconditioning, aangepaste dekken en toiletten. Als je iets stijlvols en praktisch wilt voor het hele gezin, overweeg dan om een koepelvormige glampingtent te kopen. Een luxe tent is uw beste prijs-kwaliteitverhouding. Als je ideeën hebt voor een kampeertent, kies dan voor BDIR.

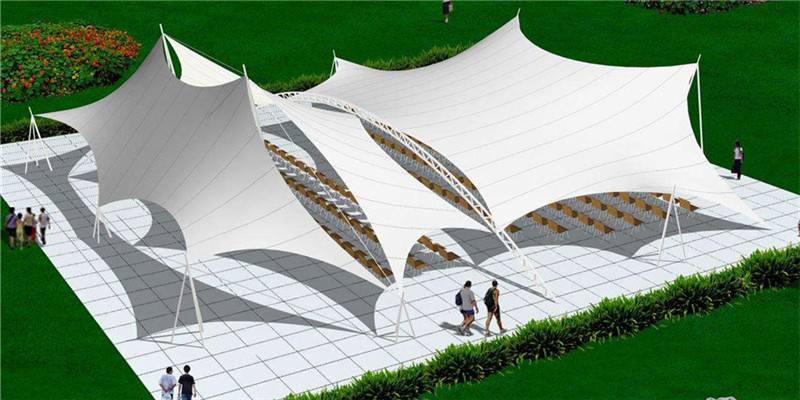

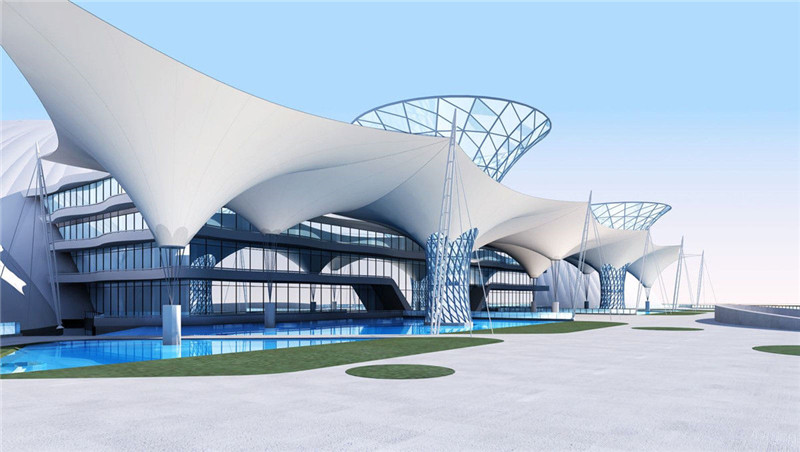

Gebruik en voordelen van trekconstructies

Een trekconstructie is een lichtgewicht weefselstructuur die lasten draagt door gebruik te maken van spanning. Stretch Structures Fabric Structures beschrijft verschillende stretchfolie structuren en de huidige stand van kennis. Trekweefselstructuren worden vaak gebruikt in transportfaciliteiten, gebouwen en andere toepassingen die een hoge mate van duurzaamheid en esthetiek vereisen. Ze kunnen ook worden gebruikt als een lichtgewicht alternatief voor stalen frames, zoals wolkenkrabbers, schaduwstructuren voor speelplaatsen, tuinschaduwstructuren, enz.

Het ontwerp van trekconstructies kan variëren, afhankelijk van de behoeften van een specifiek project. Ze worden vaak gebruikt om schaduw of schaduw te bieden aan gebouwen. De schoonheid van trekstructuren maakt ze een aantrekkelijke optie voor vele soorten faciliteiten. Ze bieden ook een unieke combinatie van betrouwbare functionaliteit en esthetische aantrekkingskracht. Deze voordelen maken ze tot zeer populaire structurele systemen. Enkele voorbeelden van trekstructuren worden hieronder vermeld. Trekstructuren kunnen worden ontworpen met grote of kleine oppervlakken. Het kan grote ruimtes bedekken, zoals evenementenlocaties, stadions, podia voor optredens of militaire constructies. Kleinere voorbeelden zijn buitenrestaurants, rooftopbars, gespannen schaduwzeilen en meer. Trekconstructie is een uitstekende keuze voor buitentoepassingen omdat het een buitengevoel geeft en weerbestendig is. Door zijn unieke membraanspanningseigenschappen heeft de trekweefselstructuur een unieke elegante vorm. De doorschijnendheid zorgt ook voor zacht, diffuus natuurlijk licht. Kunstlicht kan ook worden gebruikt om buitenverlichting te genereren. Trekconstructies kunnen worden gebruikt om geprefabriceerde modulaire gebouwen te maken of als lichtgewicht elementen van bestaande constructies. Ze zijn een van de meest kosteneffectieve opties op de markt. Wanneer ze op de juiste manier zijn ontworpen en geconstrueerd, kunnen elastische weefselstructuren zeer duurzaam zijn.

.jpg)

De Duitse architect Frei Otto was een baanbrekende figuur in de ontwikkeling van trekarchitectuur. Het baanbrekende werk van Frei Otto toont aan dat de relatie tussen architecturale en structurele vorm intiem en wederzijds voordelig is. Het monumentale spangebouw van Frei Otto, de Hangende Dach in München, won in 2015 de Pritzker Architecture Prize. Het herdefinieert structuren en geprefabriceerde systemen en laat zien dat ze compatibel zijn met duurzaam ontwerp. Stretchstoffen zijn typisch combinaties van vezels die in verschillende toepassingen worden gebruikt. Trekstructuurdetails hebben veel voordelen, waaronder de mogelijkheid om het oppervlak tussen de punten te minimaliseren. Bovendien is het zeer efficiënt en maximaliseert het het gebruik van dure, zeer sterke vezels. En omdat het licht is, is het ook duurzaam. Als u op zoek bent naar trekconstructies voor uw project, neem dan vandaag nog contact met ons op!

Spanconstructies zijn kosteneffectiever en gebruiken minder materiaal dan spanweefselgebouwen. Trekstructuren kunnen hele gebouwen creëren, waardoor ze de eerste keuze zijn voor complexe ontwerpwerkzaamheden. elastische weefselstructuren zijn meestal gemaakt van dunne stoffen die in tegengestelde richtingen worden getrokken om een dubbele kromming te creëren. De dubbele kromming verdubbelt de stijfheid van de stof. Trekstructuren kunnen grote afstanden overbruggen zonder tussensteunen.

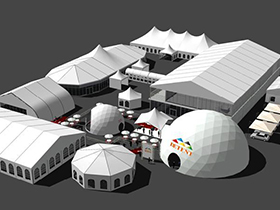

Geodetische Koepeltenten Geschikt voor Wonen en alle Soorten Activiteiten

Geodetische koepels zijn populaire locaties voor evenementen geworden. Ze zijn perfect voor een verscheidenheid aan toepassingen, waaronder tentoonstellingen, bruiloftsfeestzalen, lanceringen van persproducten, geïmproviseerde klaslokalen, ijsbanen en zelfs zwembadtenten. Je kunt er zelfs zelf een bouwen met de juiste materialen en gemakkelijk te volgen instructies. Als u niet zeker weet waar u moet beginnen, kan bdir u ingenieurs en projectmanagers sturen om u te helpen bij het bouwen van uw eigen geodetische koepel.

Canvas koepeltenten kunnen worden gebruikt met elk type tentstructuur. Omdat het geen kolommen of dragende elementen heeft, kan het vrijwel overal worden geplaatst zonder bouwvergunning. Het kan zelfs op beton worden geïnstalleerd. Vanwege hun sterkte en lichtgewicht zijn hoge koepeltenten ideaal voor een verscheidenheid aan activiteiten. Het kiezen van de juiste tentstructuur voor uw behoeften is van cruciaal belang voor een succesvol evenement.

Fuller's Geodesic Dome staat in de schijnwerpers na de Italiaanse première. De koepels waren enorm populair tijdens de Triënnale van 1954 en het Amerikaanse leger was geïnteresseerd in het gebruik ervan voor toekomstige projecten, vooral omdat ze solide huisvesting moesten bieden aan soldaten in het buitenland. Na het winnen van de Gran Premio op de Triënnale van 1954, kreeg Fuller's ontwerp een grotere publieke aantrekkingskracht. Een ander belangrijk voordeel van een geodetische koepel is de eenvoud. Het ontwerp zorgt voor innovatieve interieur- en opbergmogelijkheden. Hoewel geodetische koepels als een luxe worden beschouwd, kosten ze geen fortuin om te bouwen. Ook als u geen budget heeft voor een vaste opstelling, kunt u deze eenvoudig vervoeren en snel overal neerzetten. Pop-up evenementen zijn een geweldige plek om een geodetische koepel te plaatsen. Andere toepassingen zijn balzalen, planetaria, scholen, serres, speeltuinen en zelfs amfitheaters in de buitenlucht.

Een geodetische koepel is een halfronde dunne-schaalstructuur op basis van een geodetisch veelvlak. Deze zijn stevig en licht van gewicht en kunnen veel gewicht dragen in vergelijking met hun formaat. De Missouri Botanical Garden gebruikte een van deze om in de jaren zestig een kas te bouwen.Als u op zoek bent naar een uniek buitenverblijf, kunt u overwegen een geodetische koepel te huren. Deze tenten zijn niet alleen duurzaam en milieuvriendelijk, maar ook nog eens zeer betaalbaar. Bovendien kunnen ze een nieuwe dimensie toevoegen aan uw glamping-ervaring. Deze unieke stijl maakt het een populaire keuze voor elke gelegenheid, van gezinsvakanties tot romantische uitjes met je partner.