Desain & Produsen Struktur Membran Tarik Profesional

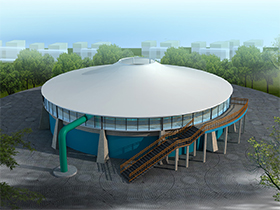

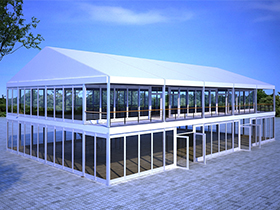

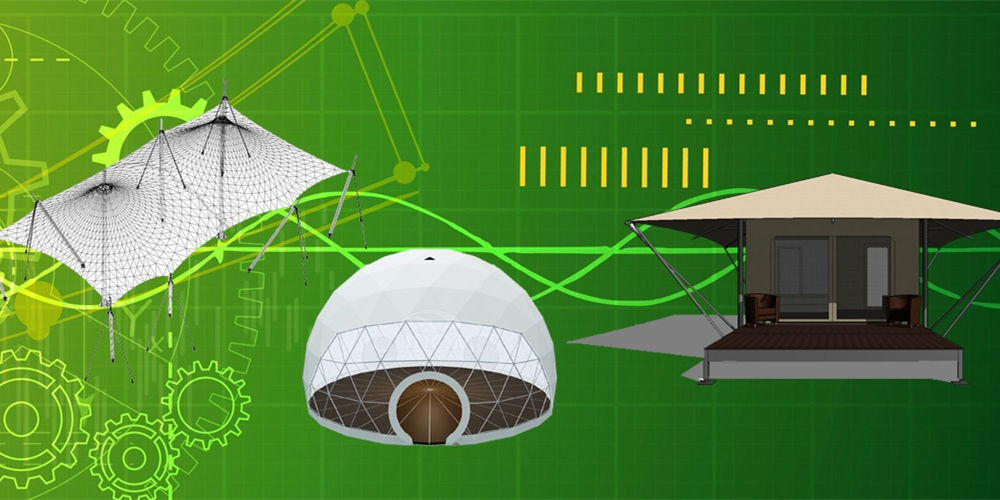

Dengan 10 tahun pengalaman dalam industri struktur membran tarik, kami telah berhasil merancang, merekayasa, memproduksi dan memasang ribuan proyek konstruksi membran tegangan tinggi di 37 negara di seluruh dunia. Struktur kain tarik digunakan sebagai atap / kanopi / teduh / berlayar / tenda untuk fasilitas olahraga, fasilitas transportasi, fasilitas budaya, fasilitas lansekap, fasilitas komersial, kanopi pengolahan limbah, tangki penyimpanan biogas, struktur membran udara, struktur membran hotel, Domes Geodesi dll Struktur kami sesuai dengan standar beban angin dan salju lokal dan internasional. Kami tidak akan pernah mengambil risiko ketika kami memberi pelanggan kami dengan struktur membran yang dikencangkan yang memenuhi persyaratan beban angin dan salju di setiap wilayah atau negara.

-

Produsen profesional

Kami berspesialisasi dalam menyediakan berbagai layanan mulai dari desain konsep hingga implementasi proyek struktur kain.

-

Layanan berkualitas

Kami menyediakan layanan cepat, berkualitas tinggi dan antusias, dan kepuasan pelanggan adalah prioritas nomor satu kami.

-

Visi Perusahaan

Kualitas adalah penyelamat perusahaan kami. Kami memiliki 0 struktur tegangan patahan dalam proyek kami selama 10 tahun terakhir.

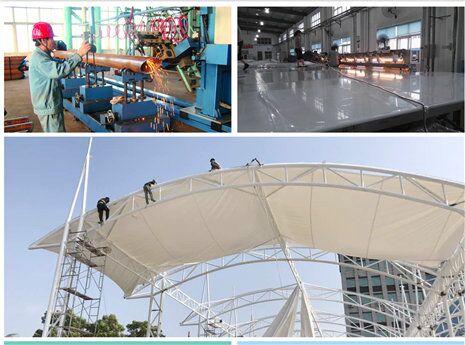

Pabrik Pengolahan Baja

Pabrik pengolahan struktur baja meliputi area seluas 3.000 m2. Ini memiliki mesin pemotong kawat CNC memotong, mesin mesin bending pipa beveling dan bengkel finishing dengan memutar, penggilingan, perencanaan dan pengeboran. Kapasitas pemrosesan struktur baja tahunan adalah 10.000 ton. Ia memiliki kualifikasi konstruksi tiga tingkat struktur baja yang dikeluarkan oleh departemen konstruksi negara yang kompeten.

Pabrik Kain

Pabrik pengolahan membran kain meliputi area seluas 5.000 m2, dengan kapasitas produksi tahunan PTEF sebesar 200.000 m2; kapasitas produksi tahunan sebesar 100.000 m2 ETFE; dan kapasitas produksi tahunan sebesar 300.000 m2 PVC / PVDF. Kami memiliki kualifikasi desain dan konstruksi struktur membran sanksi yang dikeluarkan oleh asosiasi industri.

Cara Menyesuaikan Tenda Glamping Anda Sendiri

Tenda glamping tersedia dalam berbagai model, cocok untuk liburan keluarga Anda selanjutnya. Pilih dari tenda atau demo indah yang dirancang khusus. Banyak tenda mewah memiliki spa di tempat, dinding samping berukuran 5 inci, dan cincin D baja di bagian atap. Memiliki dinding samping 6+ kaki memberi Anda lebih banyak ruang kepala dan ruang tenda yang dapat digunakan.

Glamping, juga dikenal sebagai glamping, adalah cara yang bagus untuk melepaskan diri dari kesibukan kita. Glamping adalah tempat yang tepat untuk menjauh dari teknologi dan menikmati alam, udara segar, dan relaksasi mutlak. Apakah Anda lebih suka glamping dengan tempat tidur yang nyaman, tenda bergaya unik, atau sesuatu yang benar-benar terpencil, glamping menawarkan pengalaman yang sempurna. Tenda berkemah kanvas mewah dapat dibeli secara online atau dengan mencari dealer lokal di daerah Anda. Pilih dari berbagai gaya dan ukuran untuk menemukan tenda glamping yang sempurna untuk keluarga Anda. Tergantung pada ukuran dan gaya, Anda dapat memilih dari tenda standar dengan tempat tidur tunggal atau ganda, atau tenda mewah besar dengan tiga kamar tidur. Beberapa orang juga dapat tinggal di resor tenda bersama.

Tenda mewah dapat disesuaikan dengan kebutuhan keluarga Anda. Beberapa dirancang untuk menampung hingga 20 orang, menjadikannya ideal untuk kelompok yang lebih besar. Model yang dirancang khusus menampilkan langit-langit tinggi berdiri dan banyak ruang lantai. Beberapa bahkan memiliki jendela mesh terintegrasi. Ini berarti bahwa tidak ada dua orang yang harus berkerumun. Dengan begitu banyak pilihan, menemukan tenda glamping yang sempurna tidaklah sulit. Jika menurut Anda biayanya terlalu tinggi, Anda juga bisa menganggur waktu dan tenda untuk dijual. Ini juga merupakan cara untuk mendapatkan uang kembali. Harga sewa tenda bervariasi sesuai dengan tingkat kemewahan tenda yang Anda sesuaikan

Tenda berkemah adalah cara yang elegan untuk menghabiskan liburan yang tak terlupakan. Akomodasi ini menawarkan kenyamanan modern dan dapat dilengkapi dengan Wi-Fi, AC, dek khusus, dan toilet flush. Jika Anda menginginkan sesuatu yang bergaya dan praktis untuk seluruh keluarga, pertimbangkan untuk membeli tenda glamping berbentuk kubah. Tenda mewah akan menjadi nilai terbaik untuk uang Anda. Jika Anda memiliki ide untuk tenda berkemah, pilih BDIR.

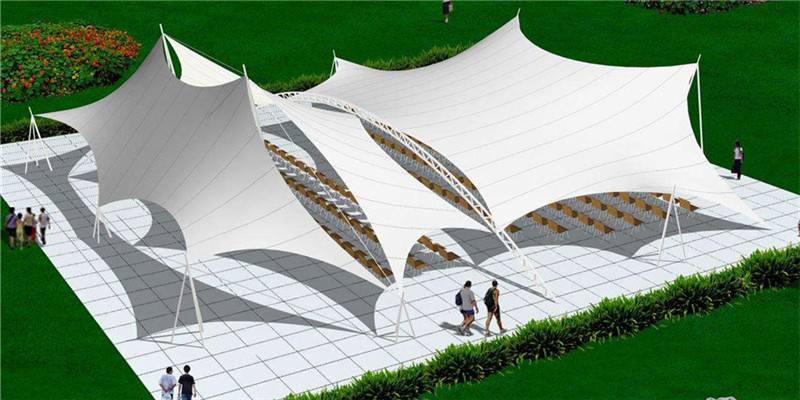

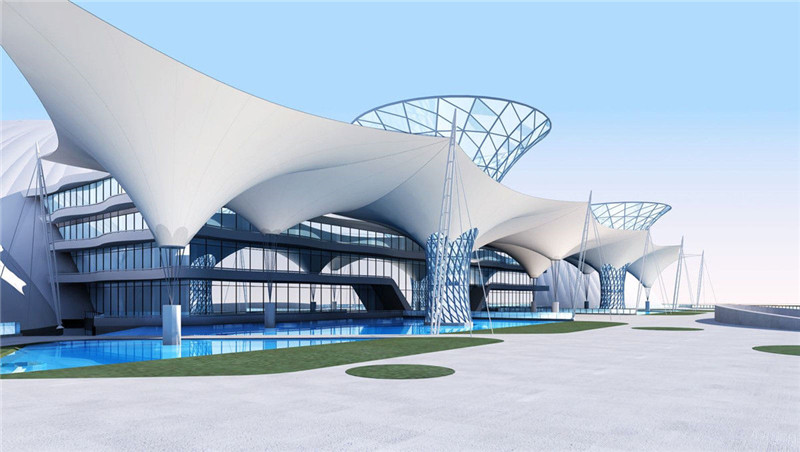

Penggunaan dan Keuntungan Struktur Tarik

Struktur tarik adalah struktur kain ringan yang memikul beban dengan memanfaatkan tegangan. Struktur Peregangan Struktur Kain menjelaskan berbagai struktur film regangan dan pengetahuan terkini. Struktur kain tarik biasanya digunakan pada fasilitas transportasi, bangunan, dan aplikasi lain yang membutuhkan tingkat keberlanjutan dan estetika yang tinggi. Mereka juga dapat digunakan sebagai alternatif ringan untuk rangka baja, seperti gedung pencakar langit, struktur naungan taman bermain, struktur naungan taman, dll.

Desain struktur tarik dapat bervariasi tergantung pada kebutuhan proyek tertentu. Mereka sering digunakan untuk memberikan keteduhan atau keteduhan pada bangunan. Keindahan struktur tarik menjadikannya pilihan yang menarik untuk berbagai jenis fasilitas. Mereka juga menawarkan kombinasi unik dari fungsionalitas yang andal dan daya tarik estetika. Manfaat ini membuat mereka sistem struktural yang sangat populer. Beberapa contoh struktur tarik tercantum di bawah ini. Struktur tarik dapat dirancang dengan area besar atau kecil. Ini dapat mencakup ruang besar seperti tempat acara, stadion, tempat pertunjukan atau struktur militer. Contoh yang lebih kecil termasuk restoran luar ruangan, bar atap, layar teduh, dan banyak lagi. Konstruksi tarik adalah pilihan yang sangat baik untuk aplikasi luar ruangan karena memberikan nuansa luar ruangan dan tahan cuaca.Karena sifat tegangan membrannya yang unik, struktur kain tarik memiliki bentuk yang unik dan elegan. Transparansinya juga memberikan cahaya alami yang lembut dan menyebar. Pencahayaan buatan juga dapat digunakan untuk menghasilkan pencahayaan eksternal. Struktur tarik dapat digunakan untuk membuat bangunan modular prefabrikasi atau sebagai elemen ringan dari struktur yang ada. Mereka adalah salah satu opsi yang paling hemat biaya di pasar. Ketika dirancang dan dibangun dengan benar, struktur kain tarik bisa sangat tahan lama.

.jpg)

Arsitek Jerman Frei Otto adalah tokoh mani dalam pengembangan arsitektur tarik. Karya rintisan Frei Otto menunjukkan bahwa hubungan antara bentuk arsitektural dan struktural sangat erat dan saling menguntungkan. Bangunan tarik monumental Frei Otto, Hangende Dach di Munich, memenangkan Penghargaan Arsitektur Pritzker 2015. Ini mengubah struktur dan sistem prefabrikasi dan menunjukkan bahwa mereka kompatibel dengan desain yang berkelanjutan. Kain stretch biasanya merupakan kombinasi serat yang digunakan dalam berbagai aplikasi. Detail struktur tarik memiliki banyak keunggulan, termasuk kemampuan untuk meminimalkan luas permukaan antara titik-titik. Plus, ini sangat efisien dan memaksimalkan penggunaan serat yang mahal dan berkekuatan tinggi. Dan karena ringan, itu juga tahan lama. Jika Anda mencari struktur tarik untuk proyek Anda, silakan hubungi kami hari ini!

Struktur tegangan lebih hemat biaya dan menggunakan lebih sedikit bahan daripada bangunan kain tegangan. Struktur tarik dapat menciptakan keseluruhan bangunan, menjadikannya pilihan pertama untuk pekerjaan desain yang kompleks. struktur kain tarik biasanya terbuat dari kain tipis yang ditarik ke arah yang berlawanan untuk membuat kelengkungan ganda. Kelengkungan ganda menggandakan kekakuan kain. Struktur tarik dapat menjangkau jarak yang jauh tanpa penyangga perantara.

Tenda Geodesic Dome Cocok untuk Tempat Tinggal dan Segala Jenis Kegiatan

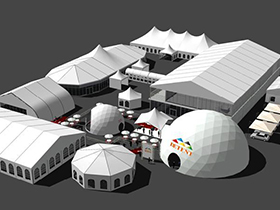

Kubah geodesik telah menjadi tempat populer untuk berbagai acara. Mereka sempurna untuk berbagai kegunaan termasuk pameran, ruang perjamuan pernikahan, peluncuran produk pers, ruang kelas darurat, gelanggang es, dan bahkan tenda kolam renang. Anda bahkan dapat membuatnya sendiri dengan bahan yang tepat dan petunjuk yang mudah diikuti. Jika Anda tidak yakin harus mulai dari mana, bdir dapat mengirimi Anda insinyur dan manajer proyek untuk membantu Anda membangun kubah geodesik Anda sendiri.

Tenda kubah kanvas dapat digunakan dengan semua jenis struktur tenda. Karena tidak memiliki kolom atau elemen penahan beban, ia dapat dipasang hampir di mana saja tanpa izin bangunan. Bahkan bisa dipasang di beton. Karena kekuatan dan ringannya, tenda kubah tinggi ideal untuk berbagai kegiatan. Memilih struktur tenda yang tepat untuk kebutuhan Anda sangat penting untuk acara yang sukses.

Kubah Geodesik Fuller menjadi sorotan setelah pemutaran perdana di Italia. Kubah sangat populer di Triennial 1954, dan militer AS tertarik menggunakannya untuk proyek masa depan, terutama karena mereka perlu menyediakan perumahan yang kokoh bagi tentara di luar negeri. Setelah memenangkan Gran Premio di Triennial 1954, desain Fuller mendapatkan daya tarik publik yang lebih luas. Keuntungan penting lainnya dari kubah geodesik adalah kesederhanaannya. Desainnya memungkinkan opsi interior dan penyimpanan yang inovatif. Meskipun kubah geodesik dianggap mewah, pembangunannya tidak memakan banyak biaya. Bahkan jika Anda tidak memiliki anggaran untuk struktur permanen, Anda dapat dengan mudah mengangkutnya dan memasangnya dengan cepat di mana saja. Acara pop-up adalah tempat yang tepat untuk menempatkan kubah geodesik. Kegunaan lain termasuk ballroom, planetarium, sekolah, konservatori, taman bermain, dan bahkan amfiteater luar ruangan.

Kubah geodesik adalah struktur cangkang tipis hemisfer berdasarkan polihedron geodesik. Ini kokoh dan ringan, dan mereka dapat menahan banyak berat dibandingkan dengan ukurannya. Kebun Raya Missouri menggunakan salah satunya untuk membangun rumah kaca pada 1960-an.Jika Anda mencari tempat peristirahatan pedesaan yang unik, Anda harus mempertimbangkan untuk menyewa kubah geodesik. Tenda ini tidak hanya tahan lama dan ramah lingkungan, tetapi juga sangat terjangkau. Plus, mereka dapat menambahkan dimensi baru pada pengalaman glamping Anda. Gaya unik ini menjadikannya pilihan populer untuk setiap kesempatan, mulai dari liburan keluarga hingga liburan romantis bersama pasangan.