Tensile Structure in Qatar

November 12,2019

State of Qatar, commonly known as Qatar. It is an Arab country in southwestern Asia. It is located in the eastern part of the Arabian Peninsula. Most of its territory is surrounded by the Persian Gulf, and its southern border is bordered by Saudi Arabia.

The oil and gas industry is the backbone of the card economy. In recent years, the government has invested heavily in the development of natural gas as the top priority of economic development. The card is the world's largest producer and exporter. Qatar is an emirate of absolute monarchy. It has been led by the "Alsani family" since the mid-19th century. It has discovered oil and natural gas under the protection of Britain in the future, replacing the original pearl industry and becoming the most important country. Source of income. Due to its rich oil resources, it has become one of the richest countries in the world. Although Qatar’s human development index is very high and its citizens are extremely rich, it cannot be recognized as a developed country because its industry and manufacturing industries are underdeveloped.

China Railway Construction Co., Ltd. and Qatar HBK Corporation form a consortium, in Doha, Qatar, officially signed the construction of the 2022 World Cup main stadium - Lucer Stadium. The contract value of the project is about 767 million US dollars, and China Railway Construction accounts for 45%. The project has a total construction period of 40 months. It plans to build 92,000 seats, with a total steel capacity of 100,000 tons and a film structure of 45,000 square meters. It is currently the world's largest roofing membrane structure construction project. The venue even exceeds the landmark building in Beijing, the Bird's Nest Stadium.

BDiR Inc. is a company specializing in the design and installation of membrane structures. We look forward to working with more Qatar customers to build more membrane construction projects to bring convenience to local people.

Car Parking Shade Companies, Manufacturers, Suppliers and Price in United Arab Emirates

January 09,2021

Are you want to find car parking shade companies, manufacturers, suppliers in uae? Want to know car parking shade price in uae? Yes, We can help you.

BDiR is a tensile structure manufacturer from China. We have many clients from the Middle East, including UAE. We chooses high quality pvc membrane, Q235 steel and accessories. We offer service from design to installation. Satisfying customers with membrane structure engineering is the eternal goal of BDiR.

Car parking shade mmmbrane structure carport features:

The carport material is selected from imported structural materials. The carport skeleton, the surface treatment uses imported marine primer, butyl acrylate polyurethane topcoat.

1. Durable: Due to the appearance of high-strength membranes and the application of tension technology, the ability of membrane structure sheds to withstand wind and rain is unmatched by ordinary awnings. Some carports use permanent membranes and can be used for three or forty years. Especially in the case of severe storms, the membrane structure is still intact and unscathed.

2. Artistic: In addition to the practical, durable, wind-proof and rain-proof functions that are unmatched by ordinary awnings, the membrane structure awning is a sculpture, a piece of art, giving people a beautiful visual enjoyment. Its softness, its curve, its softness and softness, its rich shape, its white and flawless, let people shine, long aftertaste.

3. Economics: Studies have shown that vehicles that are parked in the open air for a long time have a performance loss rate that is twice as fast as that of vehicles parked in the carport. The membrane structure awning can really protect your car and slow down the aging speed of your car. From an economic point of view, not much investment will greatly extend the life of your ride.

4. Transparency: good light transmission performance (light transmittance 20%). Exposure to sunlight does not produce yellowing, fogging, or poor light transmission.

5. Weather resistance: The surface has a co-extruded layer of anti-ultraviolet rays, which can prevent yellowing of the resin caused by solar ultraviolet rays. The surface coextruded layer has a chemical absorption of ultraviolet light and is converted to visible light. It has a good stabilizing effect on plant photosynthesis (it is very suitable for protecting all kinds of cars, valuable artworks and exhibits from UV damage).

6. Impact resistance: The impact strength of the architectural film is 250-300 times that of ordinary glass, 20-30 times that of acrylic sheet, twice that of tempered glass, and there is almost no risk of breakage. There is “not broken glass”. And the reputation of "Yuangang".

7. Flame retardant: According to the national GB8624-97 test is a flame retardant B1 grade, no fire drops, no toxic gas.

8. Temperature resistance: It does not cause deterioration of quality such as deformation in the temperature range of -40.C to +120.C.

9. Lightweight: Light weight, absolutely guarantee the safety of people and objects under the shed.

10. Sound insulation: good sound insulation.

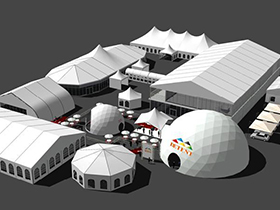

Tensile Structure in the Philippines

November 12,2019

The Republic of the Philippines, located in the Western Pacific, is a multi-ethnic archipelago in Southeast Asia with an area of 299,700 square kilometers and a population of 104.9 million (2017).

The Philippines is divided into three major island groups: Luzon, Visayas and Mindanao. There are more than 7,000 large and small islands. There are many ethnic and cultural diversity. It combines many customs of the East and West. The prehistoric Negrito may be the earliest in the Philippines. Residents, and then the migration of the nation gradually brought Malay culture, and with the development of religion and trade also brought Indian culture, Chinese culture and Islamic culture.

The Philippines is located in the southeastern part of Asia, with the West China Sea in the west and the Pacific Ocean in the east. It is an archipelago country with 7107 islands. These islands are like glittering pearls, dotted in the blue waters of the western Pacific, and the Philippines has a reputation as the "Pearl of the Western Pacific." Most of the charm of the Philippines comes from nature: top white sand beaches, small islands isolated from bathrooms, weird reefs, and unnamed mountains.

Beautifully shaped tensile membrane structure, stainless steel fittings and fasteners, combined with light and reasonable design and strict surface treatment of steel structure, create a beautiful and well-designed membrane structure, which has a wide application market in the Philippines. Inlcluding Manila, Caloocan, Davao City, Cebu, Zamboanga City, Taguig, Pasig, Cagayan De Oro City, Paranaquem, etc.

At present, the famous production enterprises of membrane structure in the world are mainly concentrated in a few developed countries such as the United States, Japan and Germany. Most of the famous production enterprises have the full business chain model of product development, design and production. As the main material of the membrane structure, the market is mainly based on PVC film, PVF film, PVDF, PTFE and even the latest ETFE film.

In China, a small number of large-scale enterprises can implement the full-service chain model operation of the research and development, design and production of spare products.

BDiR Inc. engaged in offering a complete turn-key solution for all types of Tensile Structures. We offer design, installation, fabrication and maintenance services. Our product range includes: Tensile Structure, Shade Structure, Fabric Structure, Car Parking Shade Structure, Luxury Hotel Tent, Dome Tent, etc.

If you want to know more about Tensile structure in the philippines, please contact us today: sales@bdir.com

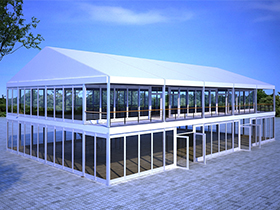

Tensile Structures in Sydeny, Tensile Membrane Structures Australia

November 07,2019

Located on the southeast coast of Australia, Sydney is Australia's largest and most populous city. The coordinates of the city center are 33°51' south latitude and 151°12' east longitude. The Greater Sydney Metropolitan Area covers an area of approximately 12,368.193 square kilometers. Sydney has an urban area of approximately 1,687 square kilometers and a population of approximately 5.03 million (2016). Sydney includes the downtown area and 33 suburbs.

Between 2012 and 2013, Sydney's regional GDP reached $33.7 billion, which is known as the “New York” in the Southern Hemisphere. Sydney has been named one of the most liveable cities in the world by UN-HABITAT for many years and was ranked seventh in the world's first-tier cities in 2018 by GaWC.

Sydney has a highly developed financial, manufacturing and tourism industry. Among them, the headquarters of the world's top multinational companies and domestic and foreign financial institutions are rooted in Sydney. At the same time, Sydney is also home to the Australian Stock Exchange, the Reserve Bank of Australia and the US 20th Century Fox Studios. Sydney is also the host city for a number of important international sporting events, including the 1938 Commonwealth Games, the 2000 Sydney Olympics and the 2003 World Cup football game.

Sydney is a beautiful city in Australia. BDiR Inc. engaged in offering a complete turn-key solution for all types of Tensile Structures in Australia. We offer design, installation, fabrication and maintenance services. Our product range includes: Tensile Structure, Shade Structure, Fabric Structure, Car Parking Shade Structure, Luxury Hotel Tent, Dome Tent, etc.

The membrane structure is widely used in waiting halls, bus stations, parking sheds, and toll booths. It is a combination of a high-strength flexible film material and a support system to form a stable curved surface with a certain rigidity and a spatial structure that can withstand a certain external load.

So what are the advantages of the membrane structure?

1. Variety of shapes and colors

As a kind of flexible material, its modeling on the building is very varied, which is unmatched by other materials. Therefore, it also creates the variable characteristics of the membrane structure, fully reflecting the shape shaping force of the building and the light and elegant dynamic curve appearance.

The multi-series color of the material further enriches the overall shape of the building. The color of the material also has good color fastness and durability, which makes the membrane structure completely free from a dull repetition of monotones, making the building and transportation facilities more colorful. .

2. The lightness of the structure

The basic components of the tensile membrane structure system are the support column, the tension cable and the membrane material. The cable exerts tensile stress on the film at the periphery to form a hyperbolic paraboloid. The diaphragm has both the structural force and the roof of the building to block the indoor and outdoor environment. The tensioned membrane structure itself is light in weight, only 1/8 of the steel structure and 1/40 of the concrete structure. The membrane structure has a good adaptability to the seismic force acting in the horizontal direction and the wind, and the structure itself has a mechanism of absorbing seismic force and wind.

3. Light transmission and heat radiation resistance

The translucency of the film creates a distinct effect with the opaque effect of the concrete or steel roof, which dims the active area and creates an uncomfortable contrast between light and dark areas. The translucency of the film gives the vision great comfort, and its light transmittance ranges from 10% to 21%, which improves the free daylighting and saves daytime light energy. The light passing through the film is perfectly scattered, reproducing the true color of the space underneath. The high reflectivity of the film (about 75%) avoids a large amount of heat radiation and reduces heat transfer, and its shading coefficient is about 0.12.

4. Durability of materials

The film material is a material obtained by weaving a fiber into a fabric substrate and processing and fixing the resin on both sides of the substrate. The center fabric substrate is divided into polyester fiber and glass fiber, and the coating material is used. The resin is polyvinyl chloride resin (PVC), polytetrafluoroethylene resin (PTFE), difluorinated resin (PVDF), and the like.

It has been confirmed by the German ENKA experiment that the thickness of the fabric coating is directly related to the life of the fabric. After reaching a certain coating thickness, the residual strength of the fabric does not change within twenty years.

5. Strong building identifiability

It is the semi-transparent nature of the membrane that makes the membrane structure a beautiful landscape at night. Through the light control, the top of the film is transparent, which can form a colorful and unique night scene effect with traditional architecture, which has strong building recognizability and labeling. The landscape effect is not achieved by any other form of architecture. Arrived

6. Economics of construction costs

In the process of installing the membrane structure, firstly, a large piece of membrane cloth is made in the factory and effective management is implemented, so that the on-site operation time and other expenses of the entire system are reduced, and the building is covered in time, and the interior decoration can be started as soon as possible. For large-scale construction, the membranes installed each time can range from 1000 to 1500 square meters. The entire installation process can save about 70%-80% of the construction period compared to other roofing materials, and the construction cost saved is considerable.

What is the Cutting and Joining Method of Tension Structure?

November 12,2019

What is the method of cutting and joining the tension structural materials? Today, BDiR technicians introduce you and hope to help you better in your life.

1. The tension structure is generally not bent and bent. The tension used is a flat coil. Therefore, it is necessary to cut the flat tension according to specific planning requirements, and then splicing into an approximate space. Qu and. In addition to the force requirements of the tension, the selection plan must meet the visual requirements. This is because the way the top of the transparent film is not easy to see, but the dark seam formed by the film joint on the transparent ceiling can be seen from the inside. Cutting seams helps people understand the roof style and dimensions and increase the readability of the top shape of the film. Therefore, the image formed by the seam of the film is an important interior decoration method and a powerful thing reflecting the space.

2. For example, the layout of the house awning of the M9edina Mosque (Schock, 1997) clearly reflects the shape of the funnel-shaped umbrella top. The picture also has a typical Muslim architectural style with a strong decorative effect. The top-level movie plan of the Kuala Lumpur National Sports Center in Kuala Lumpur is more decorative. Patchwork is a circular curve dotted with several huge flower-shaped patterns, the center of the flower just happens to be the fulcrum of the film surface. The seam design of the floral picture clearly expresses its force connection and also helps to understand the overall shape of the film surface. The entire function of the ceiling is like floating a few petals on the moving surface.

Have you learned how the tension structure manufacturer's technicians cut and join tension structural materials? If you want to know more, stay tuned.

What are the Advantages of Landscape Tensile Membrane Structure?

November 07,2019

The landscape membrane structure is some membrane structure equipment in tourist attractions, including parking sheds, rest spots and so on. Then, which company is more professional in making landscape film structure? Can there be a landscape film structure with success stories to learn from? Everything you want, BDiR Space Structure Engineering Co., Ltd. can help you solve it.

BDiR membrane structure is widely used in commercial plazas, stadiums, bus stations, toll stations, sewage pool cover membrane structures, biogas tank cover membrane structures, transportation facilities, environmental protection facilities, landscape facilities, cultural facilities, parking sheds, steel structure workshops, etc. The membrane structure is designed and installed, and the membrane material is processed. But all related to the membrane structure, BDiR is able to complete the project professionally.

Sunshade membrane structure

Landscape membrane structure engineering can provide a variety of uses and integrate with the garden landscape. Create a happy space for people to enjoy. It fully demonstrates the artistic beauty of the structural members' clear force. It subtly integrates the surrounding environment and gives people a sense of elegance, romance and warmth. In addition, due to the unique color rendering of the film structure material, it can form a colorful landscape under the mapping of nighttime lanterns. Not only provide people with space for sunshade and rain. At the same time, it is popular because of its lively shape that gives people a stylish and relaxed feeling of relaxation.

The light and compact shape of the membrane structure is used to construct a variety of semi-closed, fully enclosed spaces, which make it an all-weather building space, providing weatherproof, sun-proof and other artificial environments, and has a good advertising logo effect. The landscape membrane structure is also an excellent choice for the renovation and construction of pedestrian streets.

So, how to maintain and maintain the landscape membrane structure with so many advantages?

1. General requirements for engineering maintenance

Protection and maintenance of landscape membrane structure engineering. The surface of the membrane should not be in contact with the knife or sharpener to avoid scratching and scratching the surface of the membrane. Once the film is found to be scratched and severely scratched, effective measures should be taken in time to avoid more serious damage. At the same time, the manufacturer is notified to repair it. The surface of the steel component must not be hit and scratched by hard objects, and should not be exposed to various acids. , alkaline and organic solvents.

2. When the surface of the landscape membrane structure membrane needs to be cleaned and cleaned:

a. Workers should not wear hard-soled shoes to directly contact the surface to prevent sand from grinding the surface and severely scratching the surface of the film.

b. When cleaning the surface of the membrane, use clean water or neutral detergent. It is not suitable to use acidic or alkaline materials such as gasoline, alcohol or chlorine.

c. It is not advisable to stack foreign objects such as iron parts, chemicals or other colored materials for a long time.

3. The steel structure, steel cables, splints and bolts in the structure shall not be arbitrarily adjusted or disassembled without the approval of the manufacturer.

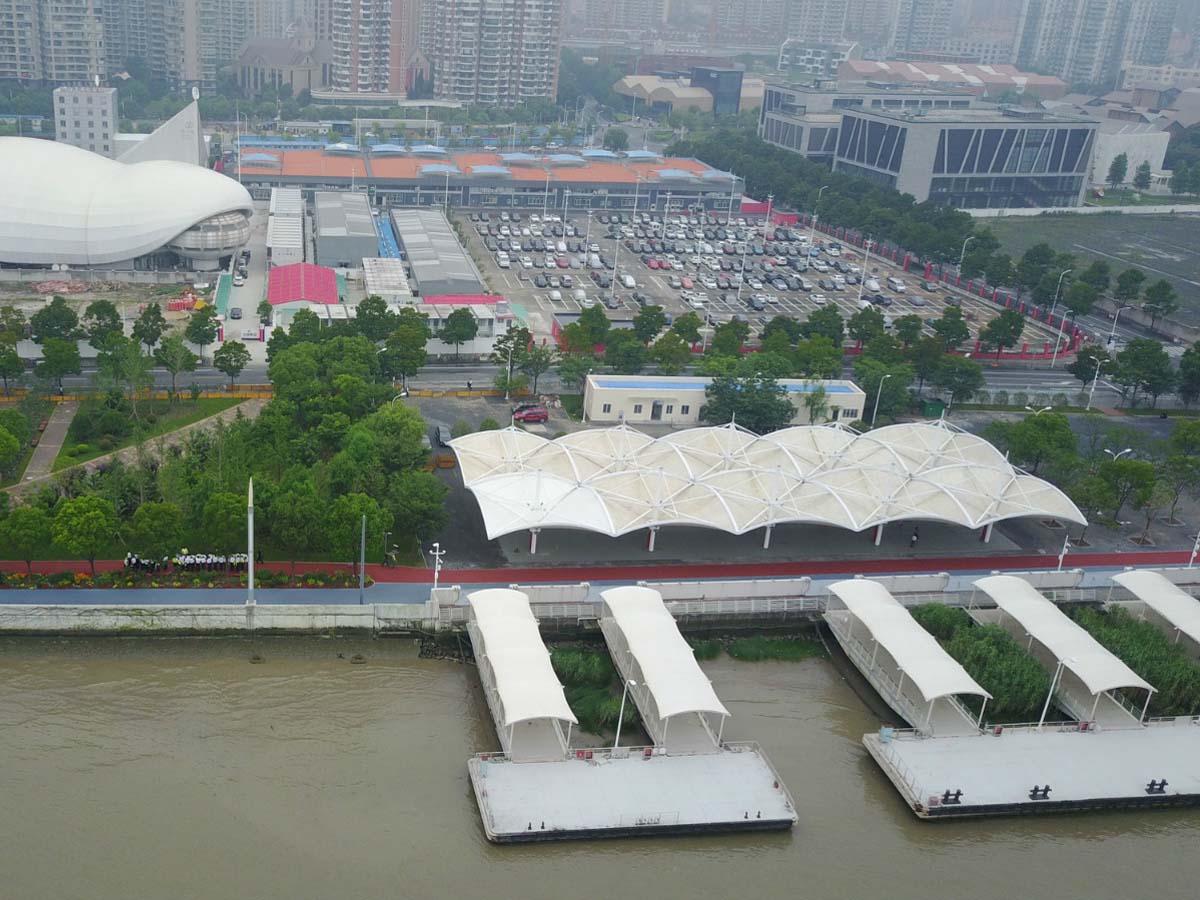

Landscape shed item of the south bank service area of Hangzhou Bay Bridge

4. It is not allowed to pull and hang heavy objects and articles on the membrane without permission.

5. Users should regularly prevent rust and maintenance of steel structure safety (half year to one year) to ensure structural safety and prevent rust water droplets from falling on the surface of the membrane.

This is the introduction and maintenance of the landscape membrane structure. If you want to know more detailed landscape membrane structure quotation design, you can call us. We have professional engineers to answer your questions. BDiR landscape membrane structure, you deserve it!

Why Should Us Build Car Parking Shade Membrane Structure?

November 12,2019

Membrane structures are used in a wider range of applications, including membrane structures in malls, transportation facilities, and landscapes. Whether it is a shopping mall or a community, parking sheds are essential. In order to protect everyone's life safety, if the construction of the membrane structure parking shed is unstable, it will cause many accidents. Therefore, pay attention to the following four points when making the membrane structure parking shed:

1. the overall frame of the membrane structure parking shed adopts square steel welded molding dragon skeleton, the whole frame is rust-proofed, the anti-rust primer is brushed three times, the surface is sprayed with white high-grade automobile paint, and the main column of the parking shed is generally 220mm steel pipe or work. The steel plate is used as the support column of the membrane structure parking shed. The overall structure of the car shed is firm and has high seismic and windproof coefficient and corrosion resistance.

2. the top sealing plate of the membrane structure parking shed is sealed with a brown color (color can be selected), and the whole frame of the car shed is riveted and fixed with a bead, which is resistant to acid and alkali corrosion and has sufficient strength to protect the vehicle in the shed;

The third point is that the inside of the membrane structure parking shed is welded with the Φ38 galvanized round pipe and the carport frame to strengthen the strength of the shed top, which makes the shed feel spacious and bright, and the parking vehicle is easy and convenient, fully complying with the requirements of the parking shed production requirements;

Fourthly, the bottom of the membrane structure parking shed is made of 10mm thick steel plate and the embedded parts are firmly welded. When the parking shed is installed, the embedded parts are poured with concrete and bolted to the vertical connection. The wind resistance coefficient is high and the carport is increased. The overall firmness can withstand typhoons above level 12.

So the question is, what kinds of materials are there in the membrane structure parking shed? In fact, it can be divided into the following two types:

The first type, a reverse tension film structure; a reverse curved shape, or a double curved saddle shape with tension and stability. Tension and stability are derived from mechanical prestressing of the film plane and its linear boundaries.

Second, the same direction bending film structure; the same direction curved shape, or a double curved spherical shape with tension and stability. Tension and stability are produced by the action of air pressure or water pressure perpendicular to the curved surface of the film. This type of structure includes an air bearing structure and an inflatable structure.

If you encounter any problems when making a membrane structure parking shed, you should consult a professional membrane structure parking shed production technician to ensure safety and energy conservation is the best, BDiR Inc. is your strong backing.

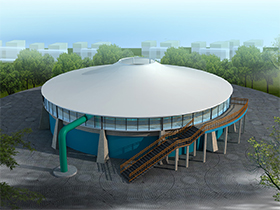

What is the Ferry Terminal Tensile Membrane Architecture?

November 07,2019

The Ferry Terminal tensile membrane architecture, as its name suggests, is the tensile membrane architecture on the Ferry Terminal. The pier, also known as the ferry, is a long levee that extends from the shore to the water. It may also be just a row of stairs that extend into the water from the shore. Most of them are man-made civil engineering buildings, or they may be naturally formed.

According to the classification of the use, the terminal can be divided into four types:

Passenger terminal

Mainly for passengers to board the ship, small passenger terminals may only be used for small vessels such as street crossings and speedboats, while large passenger terminals, such as cruise terminals, can be used for large cruise ships.

2. Freight terminal

It is mainly used for loading and unloading goods. It can be classified into public cargo terminals, container terminals, oil terminals, mineral terminals, river trade terminals and general cargo terminals.

3. Car terminal

It is for some special ship berths (mostly large special ships) to allow the cars on the land to get on the ship and the cars on the ship to disembark.

4. Container terminal

A Ferry Terminal dedicated to container loading and unloading.

With the development of the modern construction industry, the tensile membrane architecture has been applied to more and more places, and it has been widely received by enterprises and consumers. Of course, the terminal is also one of them. Whether it is a passenger terminal or a cargo terminal, or a car terminal, as long as there is a place to transport the transfer station, there is a possibility to apply the tensile membrane architecture. In particular, the passenger terminal uses a tensile membrane architecture roof at the resting point, which can play the role of sunshade and rain, which is basically the same as the function of the bus station and the parking shed tensile membrane architecture.

The Ferry Terminal tensile membrane architecture is characterized by its unique and beautiful curved surface, which is simple, bright, rigid and soft, and the combination of strength and beauty presents a refreshing feeling. The Ferry Terminal tensile membrane architecture has good environmental protection, light transmission and self-cleaning. The surface of the tensile membrane is coated with PVDF (polyvinylidene fluoride) or titanium dioxide coating, which has good heat insulation effect and can reflect solar heat. 70% off, the film itself absorbs 17%, heat transfer 13%, and light transmittance is more than 20%, after 10 years of direct sunlight, its brightness can still retain 70%.

The tensile membranes used in fireproof and shock-resistant tensile membrane architectures have excellent flame retardancy and high temperature resistance, so the tensile membrane architecture at the Ferry Terminal can also meet the fire protection requirements. Because the pier tensile membrane architecture is light in weight, flexible architecture and large deformation capacity, the seismic performance is good. Another advantage of using tensile membrane structural materials on the wharf is that the construction period is short: the cutting of the tensile membrane material, the synthetic steel architecture of the skeleton and the steel architecture of the skeleton, and the steel cable are all processed in the factory. The assembly only needs to be assembled on site, and the construction is simple, so the construction period is shorter than the traditional construction. .

Which one is better for the Ferry Terminal tensile membrane architecture company? BDiR Inc. specializes in the design and installation of Ferry Terminal tensile membrane architectures, and we can customize solutions for customers around the world.

BDiR Inc. engaged in offering a complete turn-key solution for all types of Tensile Structures. We offer design, installation, fabrication and maintenance services. Our product range includes: Tensile Structure, Shade Structure, Fabric Structure, Car Parking Shade Structure, Luxury Hotel Tent, Dome Tent, etc.

For your Tensile Structure solutions by BDiR, please contact us today: sales@bdir.com

Which Chinese Company is Good at Supply Sport Grandstand Textile Structure?

November 12,2019

The textile structure stands generally refer to the stands that use the textile structure engineering. textile structure engineering is usually built on the top of the stands to protect the sun and rain. With the continuous improvement of science and technology and aesthetic level, the beautification effect of sports stands has been paid more and more attention. The film structure is presented with its unique beautiful curved surface, which is simple, bright, rigid and soft, and the perfect combination of force and beauty. With a refreshing feeling, this is also the textile structure stand is loved by the majority of people.

So what are the advantages and characteristics of the textile structure stand? The following is by Marriott to explain to everyone. textile structure stands are a great application of textile structure engineering, and textile structure buildings can cover the entire stands very well. The tension structure of the textile structure makes the space span of the building large, and at the same time reduces the structure of the grandstand building, so that the overall weight of the textile structure grandstand structure is reduced, so that the construction is easy and safe. This is also an important reason for the choice of textile structure stands. The surface of the textile is coated to prevent the erosion of dust and rain, and to protect the textile structure from the use of the product.

The use of textile structures in sports stands can better reflect this characteristic of textile structures. Compared with traditional stands, the stadium textile structure stands the atmosphere of the stands, the lines are simple and clear, can shade and shelter from the rain, and combines practicality and elegance. It has the characteristics of beautiful shape, large space span, light weight and long service life. The structure of the stadium textile structure is beautiful and generous, and the space span is large. It better reflects the advantages of the textile structure building space span, and the construction period is short. The characteristics of textile structure are getting more and more attention. It is precisely because more and more designs use textile structure to replace traditional concrete buildings, and the textile structure is affordable, textile structure companies are also increasing rapidly, and textile structure engineering is everywhere visible.

So, if you want to be a stadium textile structure stand, which company should you choose? Of course, choose BDiR Inc.

BDiR Space Structure Engineering Co., Ltd. has been established for 10 years and is currently one of China's high-end textile structure technology companies. The plant covers an area of 30 mu, with textile processing workshop, testing workshop and steel structure finishing workshop. It is the governing unit of the China Steel Structure Association Space Structure Branch. It has the first-class qualification of textile structure contracting, the first-class qualification of design, and the third-class qualification of steel structure.

Marriott textile structure is widely used in commercial plazas, stadiums, bus stations, toll stations, sewage pool cover textile structures, biogas tank cover textile structures, transportation facilities, environmental protection facilities, landscape facilities, cultural facilities, parking sheds, steel structure workshops, etc. The textile structure is designed and installed, and the textile material is processed.

BDiR Inc. engaged in offering a complete turn-key solution for all types of Tensile Structures. We offer design, installation, fabrication and maintenance services. Our product range includes: Tensile Structure, Shade Structure, Fabric Structure, Car Parking Shade Structure, Luxury Hotel Tent, Dome Tent, etc.

For your Tensile Structure solutions by BDiR, please contact us today: sales@bdir.com

What are the Advantages of BDiR Company in Analysis and Design of Tension Membrane Structure?

November 12,2019

What are the advantages BDiR compnay in analysis and design of tension membrane structure?

In fact, the price of the design, construction, installation and installation of different sizes of tensioned membrane structures are different, depending on the actual situation. As a domestic first-class tensile film structure production and processing enterprise, BDiR can not only carry out construction and installation, but also design and produce drawings according to customers' needs. Therefore, if you have any problems related to the tensile structure of the membrane, you can consult or inquire online through the BDiR official website. So, what is the structure of the tensioned membrane? What are the application areas? What can we do specifically? The following is a detailed introduction by BDiR for everyone.

Tensile structure definition

The tensioned membrane structure is formed by stretching the membrane material on the structure by a cable. The tensioned membrane structure can also be called a tensioned cable membrane structure, which is a stable space hyperbolic tensioned membrane surface and a supporting mast system. , structural systems composed of support cables and edge cables. The tensile film structure is extremely widely used due to its high degree of flexibility and adaptability due to its image plasticity and structural form. The tensile film structure can be further divided into a cable net type and a chord type. The tensile membrane structure system is rich in expressiveness and strong in structural performance, but the construction cost is slightly higher and the construction requirements are also high.

Tensile membrane structure application field

※ Cultural facilities - exhibition center, theater, conference hall, museum, botanical garden, aquarium, etc.

※ Sports facilities - stadiums, gymnasiums, fitness centers, swimming pools, tennis halls, basketball halls, etc.

※ Commercial facilities - shopping malls, shopping malls, hotels, restaurants, shops (provocations), commercial streets, etc.

※ Transportation facilities - airport, railway station, bus station, toll station, dock, gas station, flyover corridor, etc.

※ Industrial facilities - factories, warehouses, research centers, processing centers, greenhouses, logistics centers, etc.

※ Landscape facilities - building entrance, iconic sketches, pedestrian street, parking lot, etc.

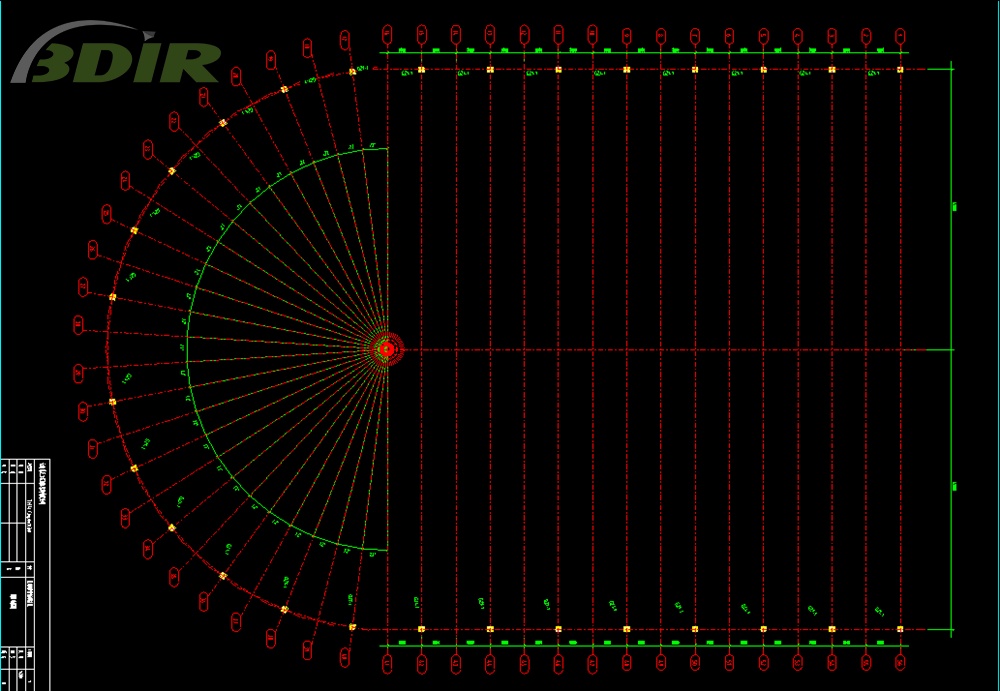

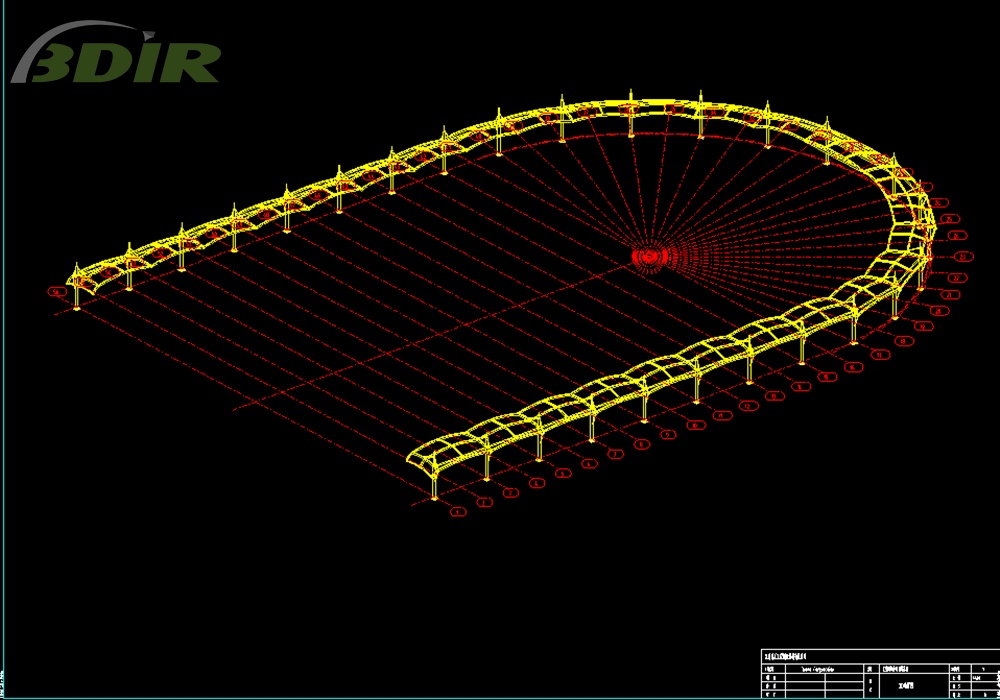

BDiR can design a full set of construction drawings of tensioned membrane structure, tensile structure effect diagrams, etc. according to customer requirements, and design special-shaped steel structures and pipe trusses. Tensile membrane structure construction drawings include mechanical analysis and calculation of tensioned membrane structure, detailed drawing of tensile structure of buried tensile structure, detailed construction of tensile steel structure steel skeleton, cutting processing of tensioned membrane material, and tensile membrane structural hardware fittings Drawings and drawings related to all tensioned membrane structures.

Tensile membrane structure design mainly includes shape determination, load analysis and cutting analysis.

Tension membrane structure construction and installation

Tensile membrane construction and installation mainly includes steel structure on-site assembly, painting process, and film installation process.

First, the steel structure on-site assembly

1. Preparation before the on-site assembly

2. Inspection and acceptance of components on site inspection and acceptance. After entering the installation site according to the design drawings and relevant specifications and components, the marking, quantity and appearance quality should be carefully checked and the inspection and acceptance records should be made. For unqualified components, acceptance and entry into the installation process are never allowed.

3. Installation process plan Ground work platform for on-site installation work.

Second, the coating process uses a new type of special anti-corrosion coating - solvent-free liquid epoxy heavy-duty anti-corrosion coating

Third, the film cloth installation process

1. Construction preparation

2, erect scaffolding according to the site construction conditions to set up scaffolding to 1 meter from the top;

3, film cloth preparation

4, filming

5, Tension

Tensile membrane structure film processing

According to the different structural methods, film processing can be divided into three categories: skeleton film processing, inflatable film processing, and tension film processing. At present, building membranes can be divided into four categories according to different properties: PVC, titanium dioxide film, PTFE, ETFE.

Archives

News at BDiR

.jpg)

Crafted with Ingenuity: BDIR Space Structures Creates a New Landmark of Spatial Art for the “San Yue San” Festival in Nanning, Guangxi

May 28,2025

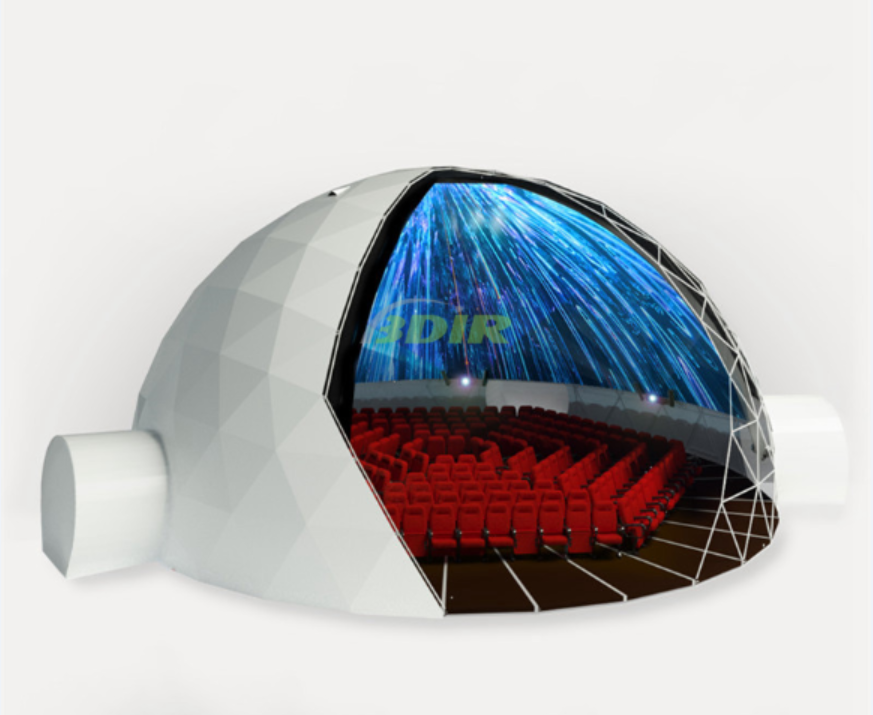

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

March 27,2025

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

March 10,2025

Watch Our Videos

Application of Air-Supported Membrane Structures in Sports Stadiums

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel