What are the Construction Methods of Membrane Structure Canopy in Bahamas

March 13,2020

The Bahamas lies east of Florida in the United States and north of Cuba and the Caribbean. The Bahamas contains 700 islands and coral reefs. Opposite the southeast coast of Florida, north of Cuba. The archipelago extends from northwest to southeast, with a length of 1220 kilometers and a width of 96 kilometers. It consists of more than 700 islands and more than 2,000 coral reefs. The total area is 13,878 square kilometers, of which more than 20 islands are inhabited. It has a subtropical climate with an average annual temperature of 23.5 ° C.

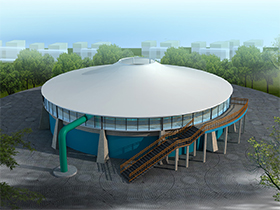

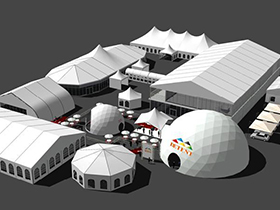

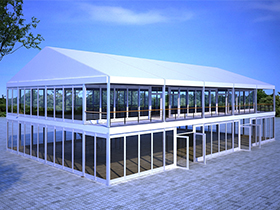

What are the construction methods of the outdoor shade cover? The success of the membrane structure canopy building, in addition to looking at the overall appearance and stability of the overall quality, the treatment of details is also very important. The quality of the welding of the membrane structure also plays a decisive role.

People often marvel at the magnificence of membrane structure buildings when they admire roof fabric, and when they see the sketches of membrane structures, they are deeply attracted by their dexterity and elegance. However, in actual construction, whether it is a large-scale membrane structure venue of tens of thousands of square meters, or a small piece of membrane structure of several square meters, it is not only composed of a single piece of membrane material, but is formed by splicing many membrane pieces.

The welding methods are hot gas welding, heating unit welding and high frequency welding, and the welding connection structure has the following methods:

First. One-sided welding of diaphragms of the same material and thickness, or two-sided welding of poor covering diaphragms.

Second. The double-sided cover membrane is staggered into thicker contacts. Staggered contacts can reduce the discontinuity of load transfer.

Third. The diaphragm with the same material and thickness is used, but the cover diaphragm is divided into two half layers and welded on both sides, so that the load can be smoothly transmitted.

Fourth. After cutting the membrane structure membrane into a tooth shape and connecting, the link length for transmitting load can be increased.

Fifth. The contacts of the high-strength double-layer membrane can be formed with thicker contacts by double-sided staggered covering membrane.

The above are the answers to the construction methods of membrane structure canopy welding. If you want to know more about membrane structure engineering, please consult BDiR Inc.

Hot Search:

Previous: Geodesic Dome Tent - Explain what is perfect Prefabricated Modular Architechture

Next: The Most Commonly used Membrane Material in Fabric Tensile Structures

Archives

News at BDiR

How to Customize Your Own Glamping Tent

July 29,2022

Tensile Structure Uses and Advantages

July 27,2022

Geodesic Dome Tents Suitable for Living and all Types of Activities

July 22,2022

Watch Our Videos

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel

Luxury Sustainable Hospitality Eco Tent Structure Villas