The Most Commonly used Membrane Material in Fabric Tensile Structures

March 16,2020

1.PTFE membrane material

PTFE membrane material refers to a composite material formed by coating PTFE (polytetrafluoroethylene) resin on a base cloth woven with ultra-fine glass fibers.

Its characteristics are: high strength, good durability, fire and flame retardant, good self-cleaning, and not affected by ultraviolet light, the service life is more than 20 years; it has high light transmittance, light transmittance is 13%, and transparent The light passing through the membrane material is naturally diffuse and does not produce shadows or glare. The reflectivity of solar energy is 73%, so it absorbs less heat. Even in the case of sun exposure in summer, the interior of the building will not be affected. Too much impact.

At present, the development and application of this kind of membrane material are relatively mature abroad, and there are many manufacturers, such as Germany Mehler Company, Verseidag Company, Japan Taiyoko-gyo Company, Zhongxing Chemical Industry Co., Ltd., United States Chemfab Company, Saudi Arabia ObeiKan Company and so on.

PVC membrane material is a composite material formed by coating PVC (polyvinyl chloride) resin on the base fabric woven with polyester fiber. The strength and fire resistance of PVC film material have a certain gap compared with PTFE. The service life is generally 7 to 15 year.

In order to solve the self-cleaning problem of PVC membrane materials, PVDF (polyvinylidene fluoride) is usually applied on the PVC coating to form PVDF membrane materials.

ETFE architectural membrane is made directly from ETFE (ethylene-tetrafluoroethylene copolymer) raw material. ETFE not only has excellent impact resistance, electrical properties, thermal stability and chemical resistance, but also has high mechanical strength and good processability.

In recent years, the application of ETFE membrane materials can replace other products in many aspects and show strong advantages and market prospects. This membrane material has particularly good light transmission. It is called "soft glass" and is light in weight. %; Good toughness, high tensile strength, not easy to tear, ductility greater than 400%; strong weather resistance and chemical resistance, melting temperature up to 200 ° C; can effectively use natural light and save energy; good acoustic performance .The self-cleaning function makes the surface difficult to be stained, and the small amount of dirt can be taken away by the rain. The cleaning cycle is about 5 years.

In addition, ETFE membrane can be pre-made into thin membrane bubbles, which is convenient for construction and maintenance.

ETFE also has shortcomings, such as the external environment is easy to damage materials and cause air leakage, high maintenance costs, but with the construction of large stadiums, tourist venues, waiting halls, etc., ETFE highlights its own advantages.At present, there are very few companies producing such membranes. Only a few companies, such as ASAHIGLASS (AGC), Asahi Glass, and Cowell, Germany, can provide ETFE membranes. The research and development and application of this membrane are not more than ten Years of history.

If you want to learn more about membrane structure engineering, welcome to BDiR Inc.

Hot Search:

Previous: What are the Construction Methods of Membrane Structure Canopy in Bahamas

Next: Large Transparent 10m Dome Tents for Commercial Activities

Archives

News at BDiR

.jpg)

Crafted with Ingenuity: BDIR Space Structures Creates a New Landmark of Spatial Art for the “San Yue San” Festival in Nanning, Guangxi

May 28,2025

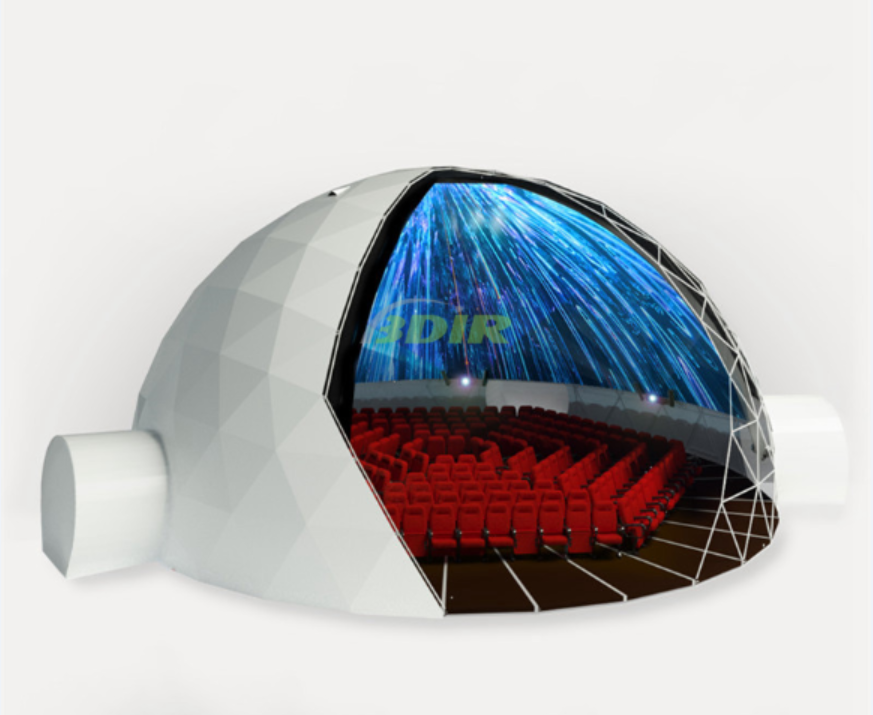

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

March 27,2025

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

March 10,2025

Watch Our Videos

Application of Air-Supported Membrane Structures in Sports Stadiums

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel