Tensile Fabric Structure Installation: Considerations for Installing Tensile Membrane

December 13,2024

Membrane structures, especially those made with PVDF membrane materials and tensile membranes, have become a popular choice in modern architecture due to their unique aesthetic appeal and outstanding performance. However, like any complex construction process, the installation of membrane structures requires careful attention to detail to avoid common mistakes that can affect their appearance and longevity. In this article, we will explore the key points to consider during membrane structure installation, highlight typical installation errors, and provide guidance on how to ensure a smooth and successful installation.

One of the most frequent issues encountered during membrane structure installation is membrane scratching. This typically occurs due to mishandling or improper use of tools. Scratches not only detract from the appearance of the membrane structure but can also reduce the durability of the material and potentially compromise its structural integrity. It's crucial that workers handle the material carefully and avoid contact with sharp objects or excessive force that could damage the surface.

A key feature of membrane structures is that the membrane must be tensioned correctly to maintain its shape and functionality. If the tension is too low, the membrane may become wrinkled or sag, which can negatively affect the aesthetic and stability of the entire structure. Proper membrane tensioning is vital to ensure the structure looks sleek and performs as intended.

The stability of the support frame is crucial for the overall integrity of the membrane structure. If the frame’s joints are loose or there are any signs of instability, the tension applied to the membrane may be uneven, resulting in deformities or, in severe cases, structural failure. Ensuring that the support frame is securely anchored and stable before beginning the installation process is essential.

.jpg)

Before starting the installation, thoroughly inspect both the membrane material and the support frame. Check the membrane for any scratches or damage, and ensure that the PVDF membrane is smooth and undamaged. It’s also important to verify that the support frame components are secure and all joints are properly connected.

Having the right tools is crucial for a successful installation. Make sure the tensioning equipment and other necessary tools are ready for use. The tensioning equipment should be capable of applying the correct force to achieve the desired level of membrane tension, ensuring that the material is taut and properly aligned.

The first step in the installation process is to gently unfold the membrane. This must be done carefully to avoid any rips or contamination. It's important to spread the membrane on a clean, flat surface to avoid dirt or debris from sticking to the material.

Once the membrane is unfolded, secure the edges using clamps or other fixing devices. This step ensures that the membrane remains in place without being overly stretched or too loose. The membrane should be slightly taut, but not yet fully tensioned.

he final step is to apply tension using the tensioning equipment. This must be done gradually to ensure that the membrane is evenly stretched across the frame. Take care to avoid over-tightening, especially in certain areas, as this can lead to wrinkles or sagging. Adjust the tension gradually, checking that the entire surface is uniformly taut.

Installing membrane structures successfully comes down to three key steps: "Inspect, Fix, Tension." Paying attention to detail in each of these stages is crucial to achieving a high-quality installation. Inspecting the materials for damage, ensuring the support frame is secure, and carefully tensioning the membrane are all fundamental to the long-term success of the project. With proper planning and attention to detail, you can ensure that your membrane structure is not only aesthetically pleasing but also durable and functional.

Hot Search: Tensile Structures,

Previous: What is a Tensile Fabric Structure? Why Load Analysis is Essential

Next: Foshan Century Lotus Sports Center: A Masterpiece of Membrane Roof Design

Archives

News at BDiR

Our Company Successfully Completes the Sunshade Canopy Project for Guangzhou Wenyuan Senior High School

August 06,2025

.jpg)

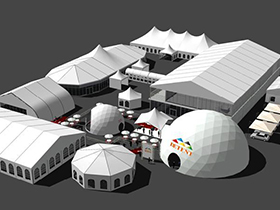

Crafted with Ingenuity: BDIR Space Structures Creates a New Landmark of Spatial Art for the “San Yue San” Festival in Nanning, Guangxi

May 28,2025

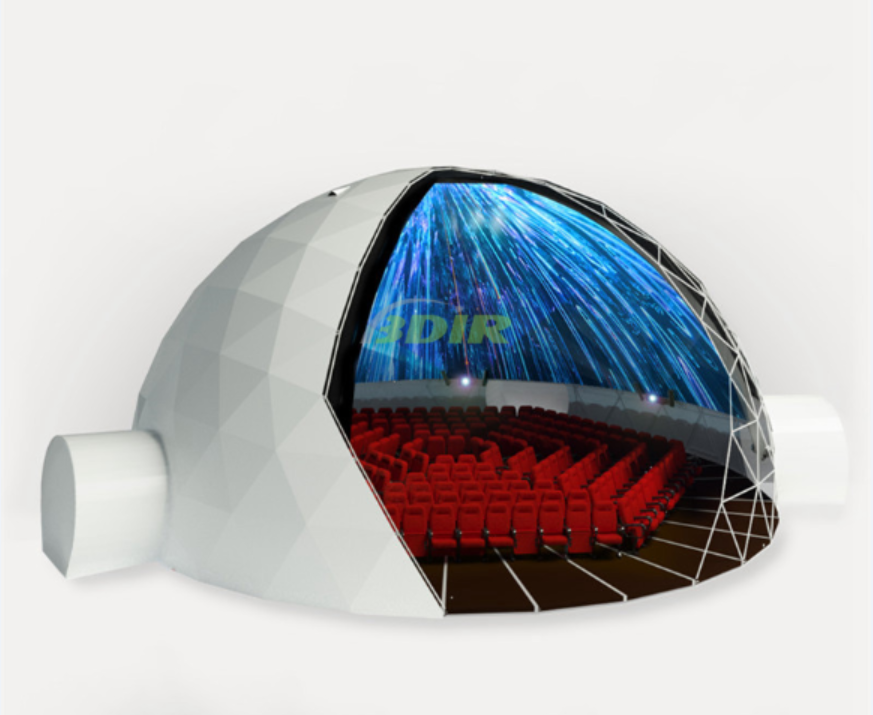

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

March 27,2025

Watch Our Videos

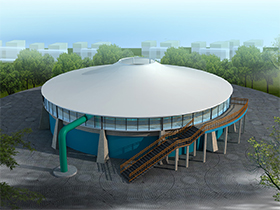

Application of Air-Supported Membrane Structures in Sports Stadiums

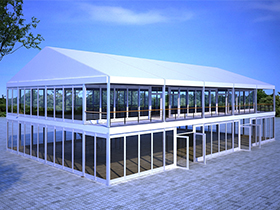

Luxury Eco Friendly Tent Structures Lodges for Tea Garden Holiday Hotel