RELATED PROJECTS

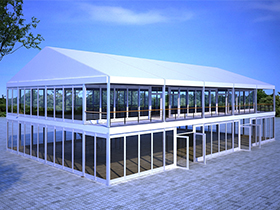

Tensile Fabric Structure for Outdoor Coffee Shop - Astana, Kazakhstan

Tensile Fabric Structure for Outdoor Coffee Shop - Astana, Kazakhstan

Luxury Outdoor Tents Hotel with PVDF Textile Structures Roof Lodges - Chengdu, China

Luxury Outdoor Tents Hotel with PVDF Textile Structures Roof Lodges - Chengdu, China

News at BDiR

Our Company Successfully Completes the Sunshade Canopy Project for Guangzhou Wenyuan Senior High School

Our Company Successfully Completes the Sunshade Canopy Project for Guangzhou Wenyuan Senior High School

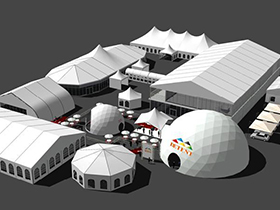

.jpg) Crafted with Ingenuity: BDIR Space Structures Creates a New Landmark of Spatial Art for the “San Yue San” Festival in Nanning, Guangxi

Crafted with Ingenuity: BDIR Space Structures Creates a New Landmark of Spatial Art for the “San Yue San” Festival in Nanning, Guangxi

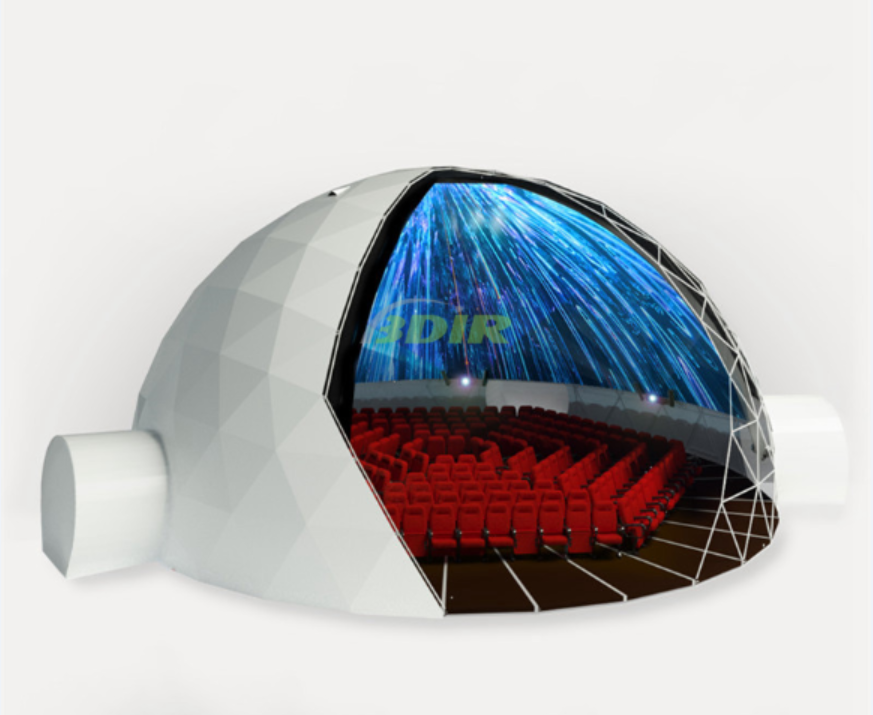

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

360° Holographic Projection Dome: Technical Analysis and Applications of Immersive Dome Systems

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

Luxury Glamping Hotels: Pioneering a New Chapter in the Fusion of Luxury and Nature

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

BDIR Stage Membrane Structures: Redefining Event Spaces with Innovation

Description

Specifications

-

√. Large Span: Tensile Structures can create an expansive covered area, exceed to 200m.

-

√. Unique Design: Tensile fabric Structure gives architects, designers, and engineers the opportunity to experiment with form and create visually exciting and iconic structures.

-

√. Various Shape: Changeful supporting structure can make lots of different shapes of tensioned structure with flexible membrane.

-

√. Cost-effective: About 1/3 to 1/2 lower than conventional structures on costs.

-

√. Easy to Install: Faster and more cost-effective in comparison to traditional construction projects.

-

√. Weatherproof: Durable and designed to withstand even the most severe weather conditions. Provide protection from both the rain and sun.

-

√. Excellent Durability: Fabric tensile Structure is characterized by durability and longevity, can be built in different areas around the world, from the frigid arctic pole to the scorching desert heat.

-

√. ECO Friendly: Have high sun reflectivity and low solar absorption. As a result, less energy is used in the building, ultimately reducing the cost of electricity.

-

√. Low maintenance Needs: Tensile membrane Structures require minimal maintenance for clients, whether use of PVC, PVDF, PTFE or ETFE.

-

√. Outstanding Natural Daylighting: Membrane is translucent, In daylight, tension structures could offer rich soft diffused naturally daylight space, and at night, artificial lighting can make it bright and colorful.

-

Design & Model

Installation

|

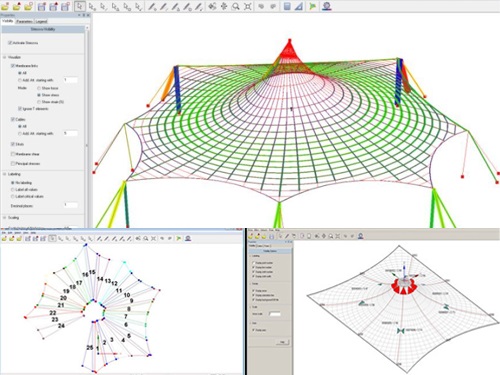

Step 1: Design BDiR use the latest tensile structural design software to produce detailed tensile structural designs. Including: BIM model design (building information modeling), finding and load analysis, integrated building design, joint force analysis, membrane cutting analysis, construction process simulation, numerical wind tunnel simulation. |

| Step 2: Membrane Fabrication Membrane fabrication plays an important role in the tensile structure. There are many fabrics (PVC, PVDF, PTFE, ETFE) in the market, they come from all over the world, they have different characteristics and prices, different welding or joining techniques. We will make the best choices from structural design, project location and our customer budget. |

|

|

Step 3. Steel Fabrication Tensile structure are made of steel structural members that are welded and painted in our factory. We will conduct the following procedures with high standards: Paint thickness detection, ultrasonic testing, magnetic particle testing, high-strength bolt torque testing, cable pre-tensioning, rust removal , pre-assembly inspection, painting, etc. |

| Step 4: Cable Fabrication Cable and hardware fittings are procured from the most reliable and certified vendors of the industry in compliance with the international quality standards. Cable fabrication are proceed under guidance of our skilled and experienced experts. |

|

|

Step 5: Installation The installation of the tension structure is critical to the overall success of the project. We will provide on site installation service. Our project manager will work with the client to coordinate the structure installation on site. Including steel structure installation, membrane lifting and measure tension. If you prefer self-installation, we'll send you detailed instructions so it can be easily installed. |

| Step 6: The Future Our service will not end at the time of delivery and installation! Because we only use the highest quality membrane materials and steel frames, cables and parts. You can rest assured that your new tensile structure is built to last. Besides, Tensile structure does not require much maintenance and we offer a up to 35 year warranty. |

|

Reviews

-

Mr. Tuan, Project Manager" BDiR has taken advantage of an idle area of the factory, creating a vast space for us. "