RELATED PRODUCTS

Golf Driving Range Roof - Tensile Fabric Shade, Canopy for Golf Course

Golf Driving Range Roof - Tensile Fabric Shade, Canopy for Golf Course

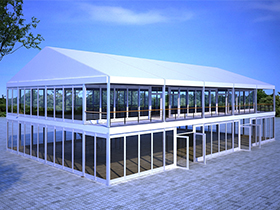

Tensile Fabric Structure for Swimming Pool - Pool Bar Shade Canopy

Tensile Fabric Structure for Swimming Pool - Pool Bar Shade Canopy

Table Tennis Court Canopy Covers - Build Health Club Shade Fabric Structures

Table Tennis Court Canopy Covers - Build Health Club Shade Fabric Structures

Landscape Tensile Structures - Permanent Fabric Shade Canopy Structures

Landscape Tensile Structures - Permanent Fabric Shade Canopy Structures

Tensile Structure for Urban Park Pavilion - PVC Coated Architectural Membrane Structure

Tensile Structure for Urban Park Pavilion - PVC Coated Architectural Membrane Structure

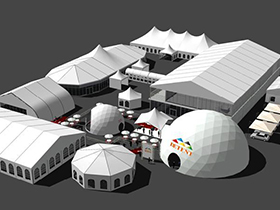

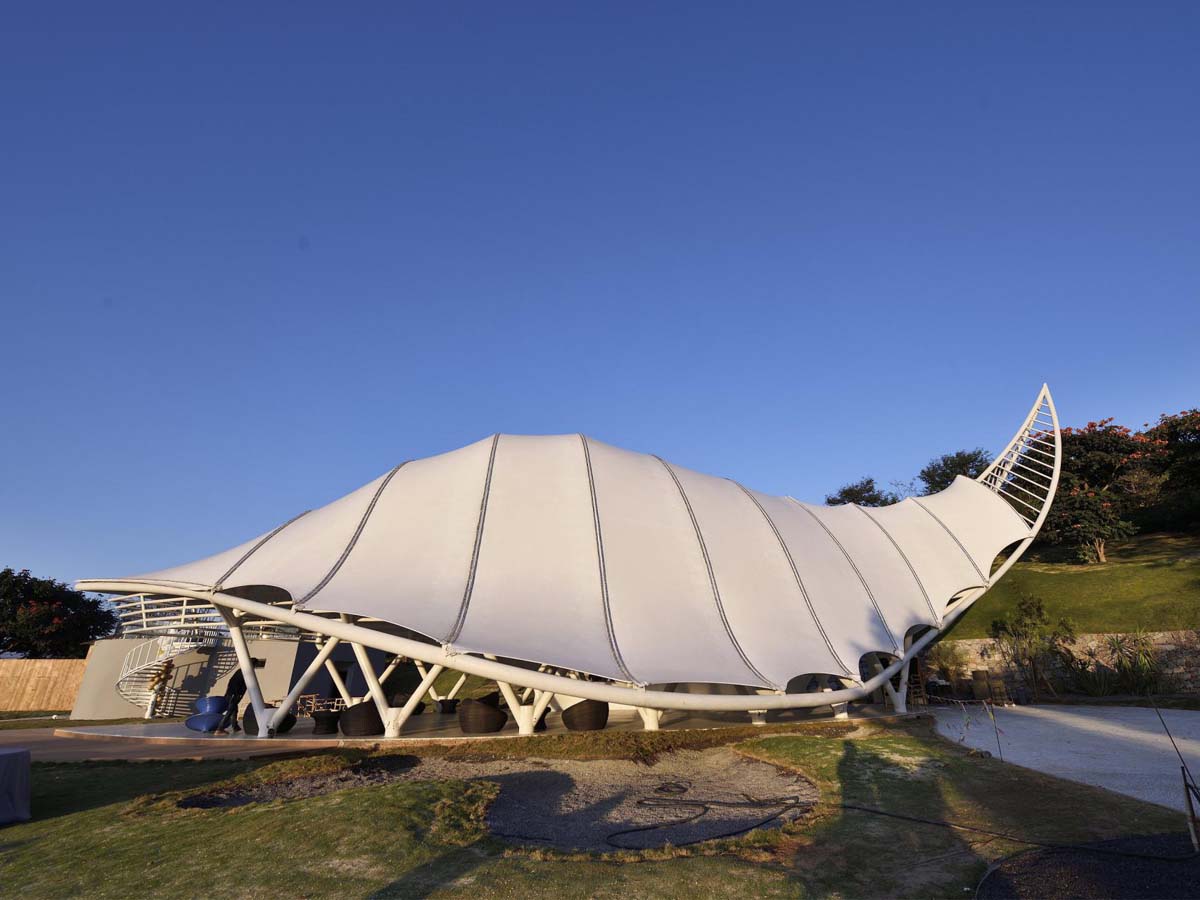

Customize Tensile Structure for Recreational Resorts, Tourism Industry

Customize Tensile Structure for Recreational Resorts, Tourism Industry

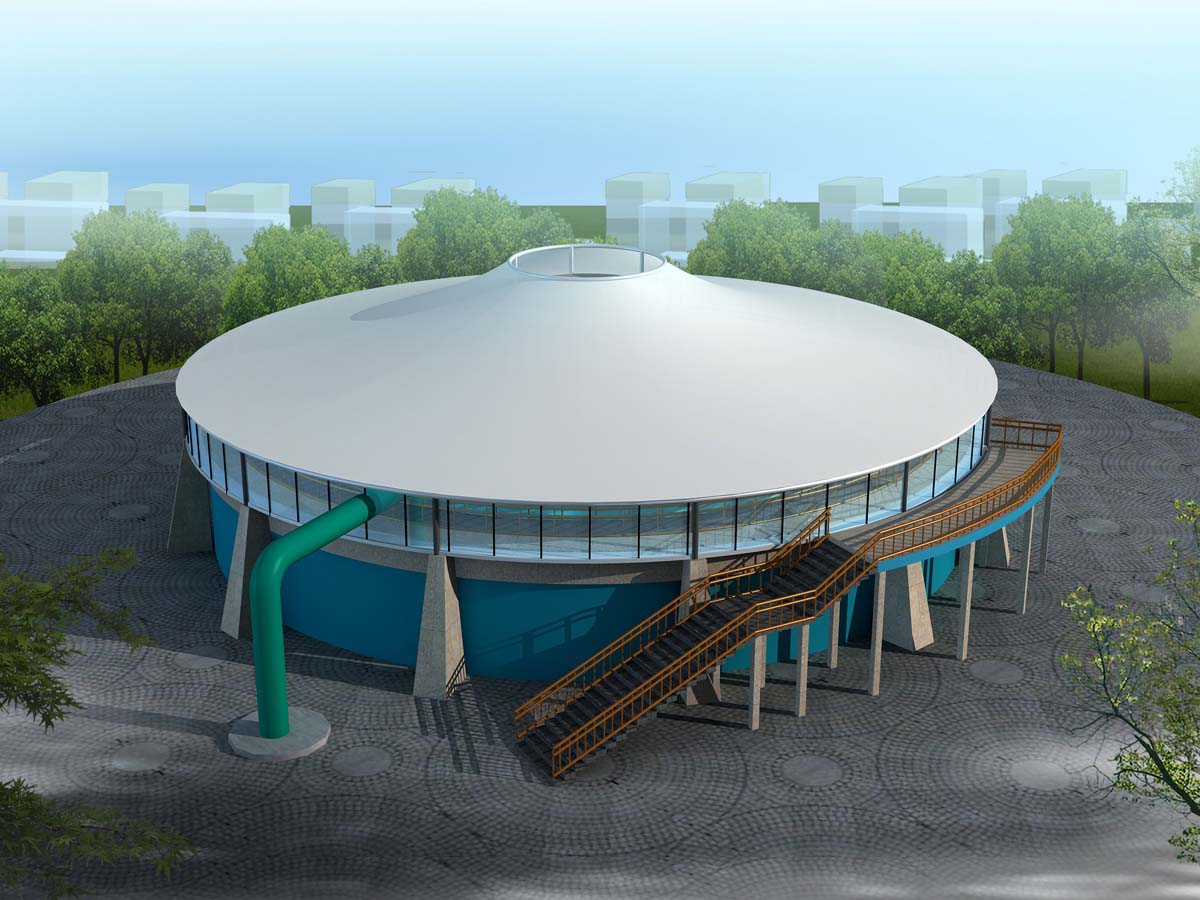

Tensile Canopy Structures for Seaside Sewage & Wastewater Treatment Plants

Tensile Canopy Structures for Seaside Sewage & Wastewater Treatment Plants

Tensile Structures for Amphitheater, Open Air & Outdoor Theater Canopy

Tensile Structures for Amphitheater, Open Air & Outdoor Theater Canopy

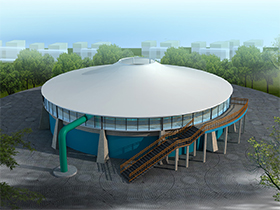

PVC PVDF PTFE Tensile Structures for Aquarium, Science Museum, Seaquarium

PVC PVDF PTFE Tensile Structures for Aquarium, Science Museum, Seaquarium

Tensile Structure in College, Campus, Junior & Middle School Play Ground

Tensile Structure in College, Campus, Junior & Middle School Play Ground

News at BDiR

How to Customize Your Own Glamping Tent

How to Customize Your Own Glamping Tent

Tensile Structure Uses and Advantages

Tensile Structure Uses and Advantages

Geodesic Dome Tents Suitable for Living and all Types of Activities

Geodesic Dome Tents Suitable for Living and all Types of Activities

Luxury Glamping Tent Or Custom Glamping Tent

Luxury Glamping Tent Or Custom Glamping Tent

Advantages of a Custom Dome Tent

Advantages of a Custom Dome Tent

Description

Specifications

-

Tensile Structure Basic Performance Parameters:

- Material Thickness: usually 0.05mm-0.82mm

- Weight (Gsm): 700 - 1100g per square meter

- Gutter: Inbuilt Gutter System

- Temperature: -40 to +70 (degree celsius)

- Tensile Strength: 2500-4000N

- Tear Strength: 520-580N

- Fire rating: DIN4102 B1/SGS M2

- Wind Load: 120 km/h

Tensile Structure Features:

- √. Personalized Customization - We have different types of tensile structures available in various sizes, shapes, and colors depending on areas as per client's requirement.

- √. Versatile - Tensile structure is the ideal solution for a wide range of applications. Can be used in a variety of occasions around the world, including sports, transportation, business, landscape, industry, agriculture, hotels and more.

- √. Aesthetical and unique designs - Take any shape and almost any size.

- √. Coverage - Light weight, Cover a large area with minimal disruptions, expanding outdoor living areas.

- √. Outstanding Translucency - Provides natural lighting and reduce heat transmission.

- √. High strength and intensity - Durable and long lasting nature, withstand the worst winds, the harshest sun and the wettest weather for very long life.

- √. Easy to clean - Aggressive dirt can be cleaned with normal detergent soap and water.

- √. Cost Effective - Perfect weldability. Ease of fabrication. Easy to install. Ease of maintenance.

- √. Eco friendly - Recyclable and Easy to move relocation or renovation.

- √. Rich colors available - Vibrant colors of membrane can create a landmark structure.

Tensile Structure Function:

- √. All Weather protection, perfect UV resistance, Waterproof, Wind proof, Snow proof, Shake proof.

- √. Completely heat and water resistant.

- √. High abrasion resistance, Anti-aging, Anti-static, high light transmission.

- √. Fireproof, Flame Resistant, Moisture proof, Smoke proof, Soundproof, Self-cleaning.

Why choose BDiR Tensile Structure?

- √. We are the leading manufacturers, exporters, suppliers and installers of all types of tensile structures.

- √. Our products are manufactured using high quality PVC / PVDF / PTFE / ETFE membranes and steels , strictly accordance with industry standards.

- √. We offer a complete turn-key solution for all your tensile fabric structure needs.

- √. We offer a budget-friendly market price for all our clients.

- √. We ensure that your project will be delivered and installed with excellent efficiency, on time and on budget.