RELATED PRODUCTS

News at BDiR

How to Customize Your Own Glamping Tent

How to Customize Your Own Glamping Tent

Tensile Structure Uses and Advantages

Tensile Structure Uses and Advantages

Geodesic Dome Tents Suitable for Living and all Types of Activities

Geodesic Dome Tents Suitable for Living and all Types of Activities

Luxury Glamping Tent Or Custom Glamping Tent

Luxury Glamping Tent Or Custom Glamping Tent

Advantages of a Custom Dome Tent

Advantages of a Custom Dome Tent

Description

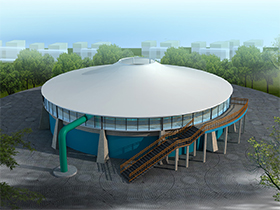

The air pillow type membrane structure is an air pillow formed by using the pressure difference between the inside and outside of the membrane surface. Air pillows and their combinations can be used as roofing or facade envelopes. In order to make the air pillow roof have good light transmittance and thermal insulation effect, ETFE film is used. An inner membrane can be added inside the air pillow to reduce the convection of the gas, thereby improving its thermal insulation effect.

ETFE air pillow membrane structure is a more patented membrane structure. As a roof and curtain wall system, it is more energy-efficient and more beautiful than traditional glass or metal roofing.

The composition of air pillow membrane structure:

1: ETFE membrane material (2 ~ 5 layers)

2: Aluminum alloy profile fixing system

3: Gas supply and intelligent control system

4: Auxiliary-intelligent fire fuse system

ETFE air pillow membrane structure with perfect lighting configuration is the best combination to create city highlights

Specifications

-

Features of ETFE Tensile structure:

"ETFE" is an ethylene - tetrafluoroethylene copolymer. ETFE fabric material has high tensile strength, impact strength and tear resistance. The thickness of the ETFE fabric material is usually 0.05 to 0.25 mm. As the thickness increases, the hardness of the fabric will increase, and it will also be more brittle, thus increasing the difficulty of processing. The typical usage of ETFE materials is to "weld" two or three layers of membrane materials together and transport them to the construction site. Then inflate them into an air pillow.

1. The ETFE material is made of fluoroplastic, which can apply pre-tension like fabric material;

2. With resistance to temperature changes, can be directly exposed to the temperature of -200 ℃ -150 ℃;

3. The transmittance of ETFE fabric can be as high as 95%. It cannot block the transmission of ultraviolet light and other light to ensure natural light inside the building. Through surface printing, the translucency of the material can be further reduced to 50%;

4. It has the characteristics of high anti-fouling and easy to clean, usually natural rain can remove dirt;

5. The ETFE fabric meets the B1, DIN4102 fire rating standards and will not drip when burned. The thickness is usually 0.05mm to 0.25mm, and the weight of the membrane is very light, only 0.15kg to 0.35kg per square meter. Even in the case of fabric melting caused by smoke and fire, it has a strong advantage;

6. ETFE fabric materials are recyclable materials, which can be reused to produce new membrane materials, or other ETFE products can be produced after separating impurities;

7. Strong corrosion resistance, and at the same time, it has strong adhesion characteristics unique to metal, which overcomes the non-adhesion defect of PTFE to metal, and its average linear expansion coefficient is close to that of carbon steel, making ETFE (F-40) Become an ideal composite material with metal, with excellent negative pressure resistance;

8. The service life of ETFE membrane is at least 25 to 35 years, which is an ideal material for permanent multi-layer movable roof structure;

9. Generally used in the form of air cushions in buildings, the economic span of air cushions is generally 3 ~ 5 m. Multiple air cushions can be connected together by steel structure, aluminum alloy structure or cable net to form a large coverage space.

Where can you put the ETFE Roof & Facades?

ETFE Fabric materials have a wide range of applications. For example: sports and leisure (gymnasiums, stadiums, fitness centers, leiure centers, etc.), tourism and transit platforms (waiting halls, station platforms, parks, etc.), arts and culture (theater, exhibition hall, concert hall, sculpture, etc.) Business (exhibition hall, sewage plant, greenhouse, billboard, etc.).