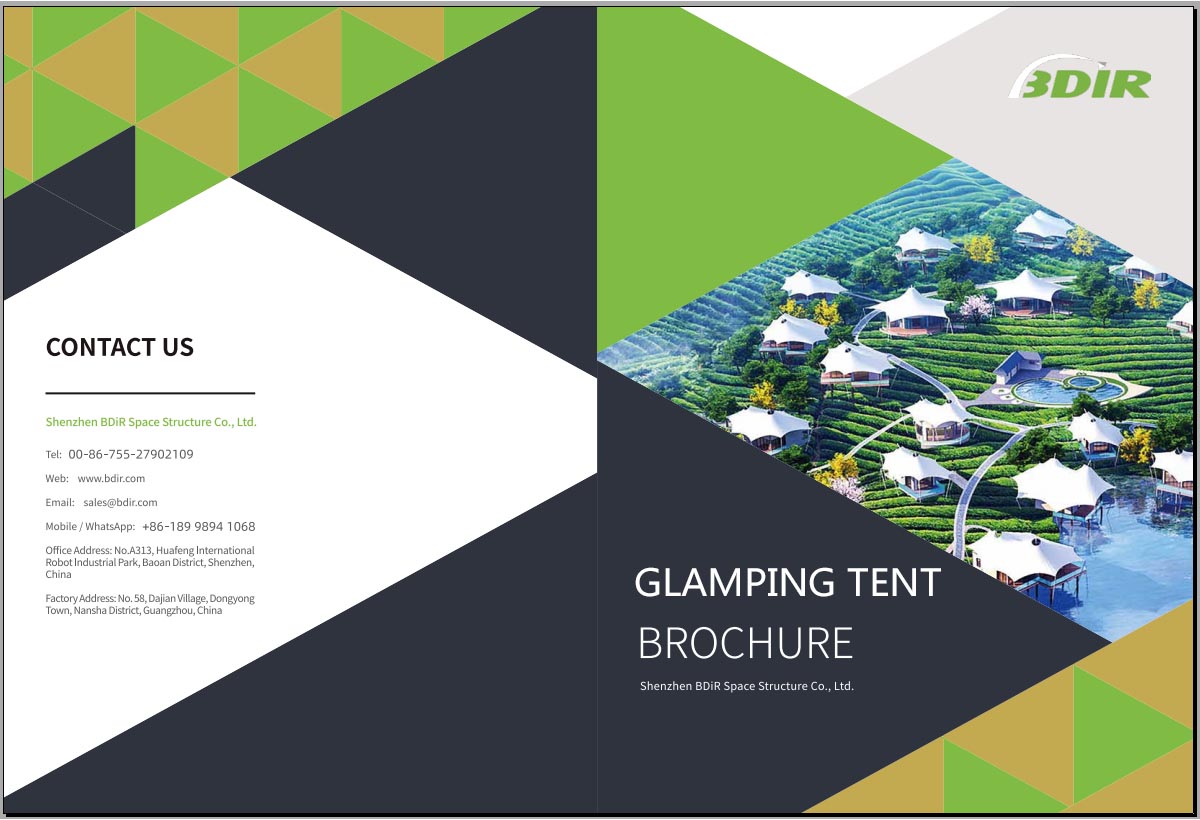

Glamping Dome Projects

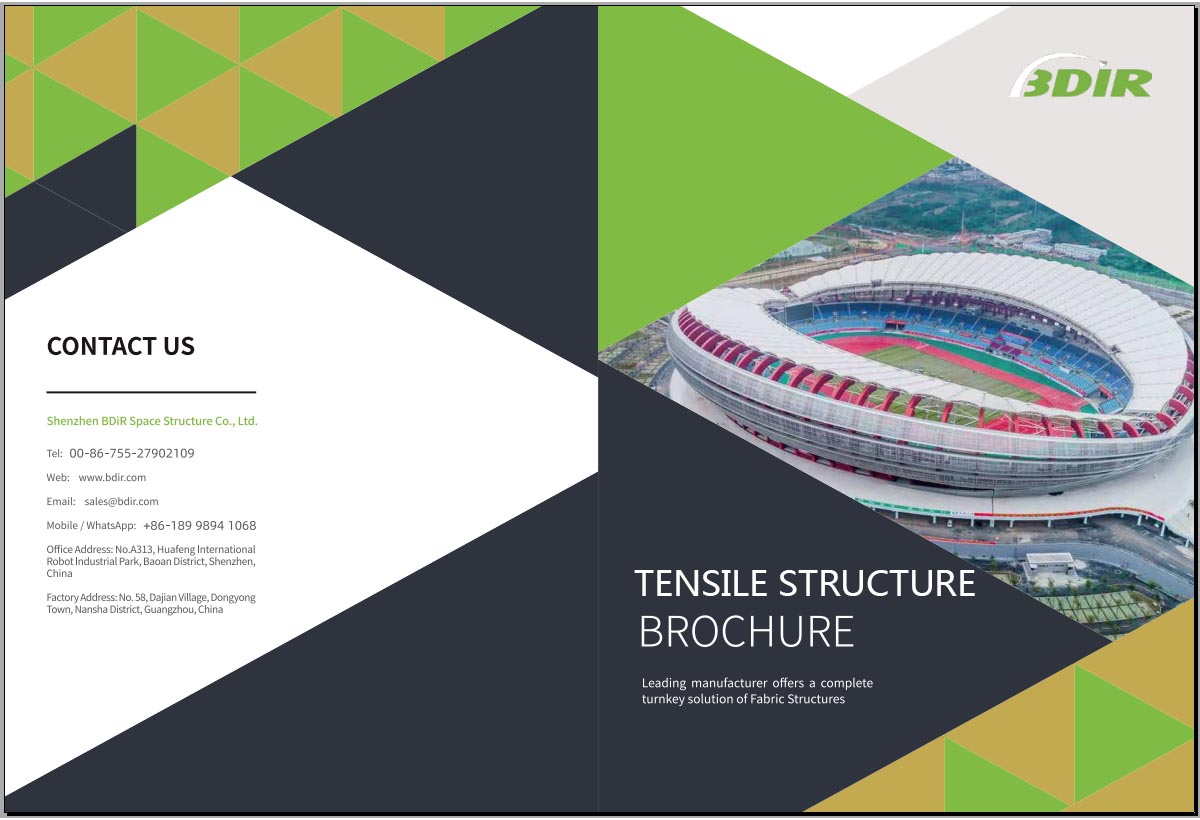

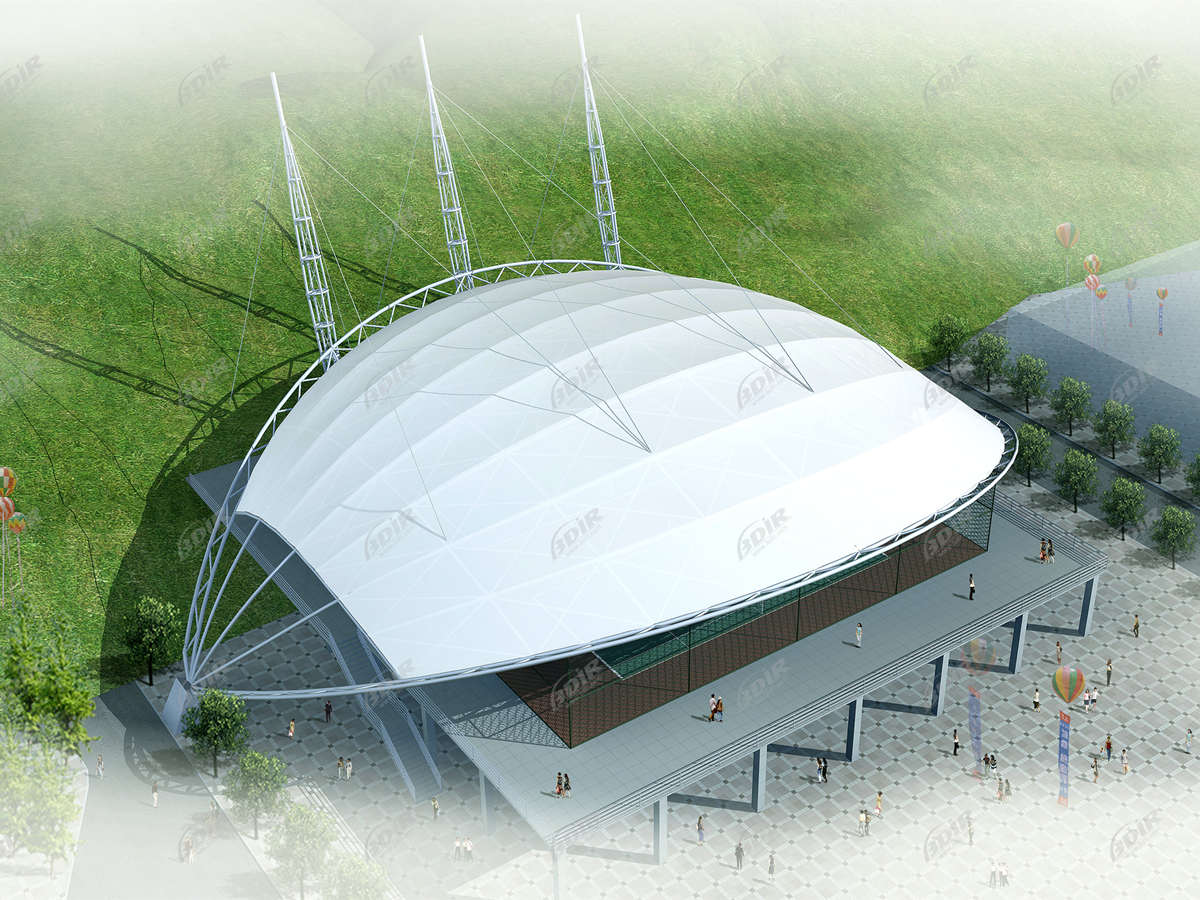

Tensile membrane Structure is a new type of building structure developed in the middle of the 20th century. It is made up of a variety of high-strength & thin fabric materials and reinforcing members (steel frame, steel column and steel cable). Stress forms a big spatial structure that supports the covering lightweight fabric membrane and can withstand external loads.

Tensile membrane structure technology is applied to a category in the field of architectural engineering. The fabric structure engineering includes modeling design, mechanical analysis, fabric cutting design, fabric production and installation, the fabrication and installation of support structures or components. It is a multidisciplinary cross-application project integrating architecture, engineering structure and materials science.

Service Category

Hot Product

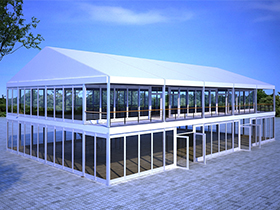

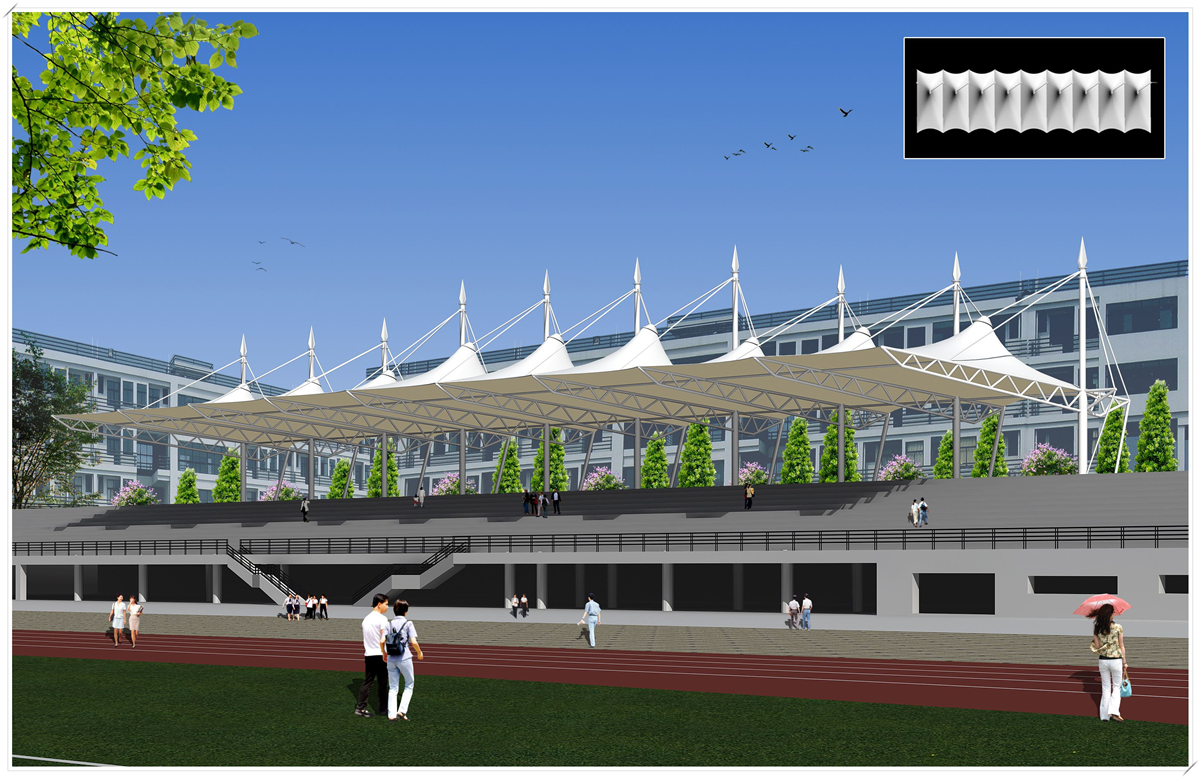

Customize Tensile Structures for Bleacher, Spectator Grandstands Roofs

Experience Luxury & Nature Accommodation in Eco Friendly Glamping Dome Cabins

Geodesic Domes Pods Tent | Glamping Pods | PVC Dome Kits - Design & Manufacturing

Glamping Domes Tent | Luxury Camping Dome Homes - Portugal

.jpg)

Dome Lodge | Geodome House | Geodesic Domes Tents - Design & Manufacturing

.jpg)

Geodesic Dome Hotel | Geodome Hotel | Eco Dome Hotel | Sun City Camp Domes

Luxury Riverside Glamping Tent Resort with Tented Lodge

Monteverde Glamping Unique Experience with 6 Geodesic Domes Tent Pods

Golf Driving Range Roof - Tensile Fabric Shade, Canopy for Golf Course

Eco Friendly Dome Tents Hotel | Patagonia Sustainable Camping Domes Resort

Picture Gallery

-

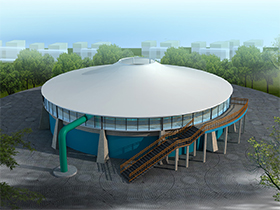

Tensile Structure of Shenzhen Dameisha

Tensile Structure of Shenzhen Dameisha

-

Tension Structure Sunshade for Tennis Court

Tension Structure Sunshade for Tennis Court

-

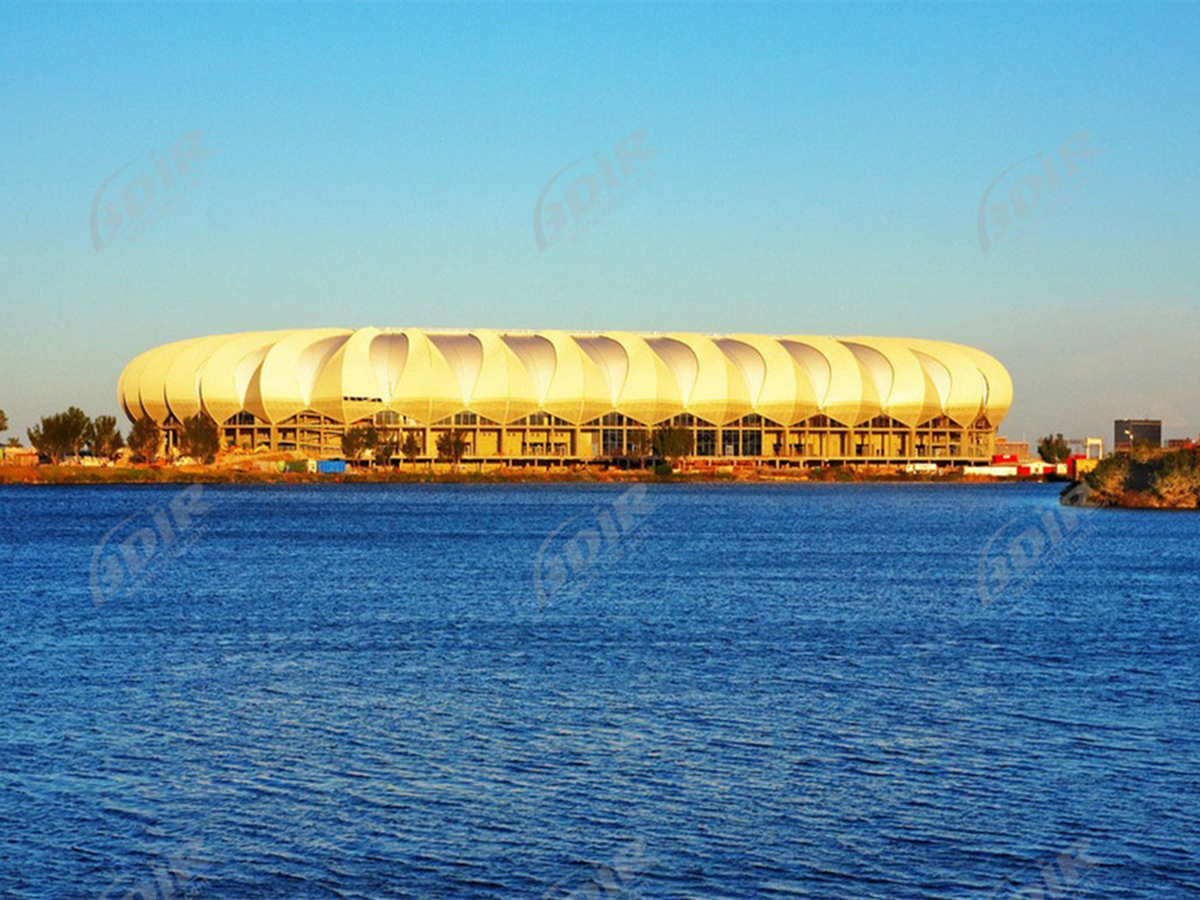

Tension Structure of Mandela Bay Stadium

Tension Structure of Mandela Bay Stadium

-

Stadium Shading Tensile Membrane Structure

Stadium Shading Tensile Membrane Structure

-

Petrol Gas Station

Petrol Gas Station

-

Stadium Tensile Structure

Stadium Tensile Structure

-

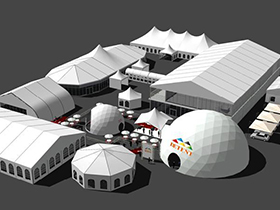

Glamping Dome Projects

Glamping Dome Projects

-

Shade Structures-Tensile Structure

Shade Structures-Tensile Structure

-

Millennium dome of Thames England

Millennium dome of Thames England

-

Brochures & Catalogue

Brochures & Catalogue

Brochures Download

Fabric Specifications

| Heytex PVC Fabric H5574-0289 | 88.8kbMM |

| Heytex PVC Fabric H5573-0289 | 88.6kbMMMM |

| Heytex PVC Fabric H5571-0828 | 266.4kbMMMMM |

| Sattler PVDF Fabric 1-648 | 278.2kbMM |

| Sattler PVDF Fabric 2-669 | 220.6kbM |

| Sattler PVDF Fabric 3-659 | 224.5kbM |

| Nowoflon ETFE Fabric 150 | 98.2kbM |

| Nowoflon ETFE Fabric 250 | 98.5kbM |

| Verseidag PTFE Fabric 1-B18919 | 108.4kbMMM |

| Verseidag PTFE Fabric 2-B18089 | 107.3kbMMM |

| 650gsm B1 Flame Retardant Report | 217.9kbM |

| 750gsm B1 Flame Retardant Report | 240.2kbM |

| 850gsm B1 Flame Retardant Report | 306.5kbM |

| 650gsm Fabric Technical Report | 201.5kb |

| 850gsm Fabric Technical Report | 198.9kb |

Sustainability

Technical Specifications

BDiR Inc. provides construction specifications in the CECS15:2004 standard for tensile membrane structures using PTFE, PVC, and PVDF materials.

1. In order to ensure safety, reliability, advanced technology and economical rationality in the design and construction of membrane structure, this regulation has been specially formulated according to the design, construction experience and technical and economic development requirements of our company for many years.

2. This regulation is applicable to general permanent and temporary civil building roofs and structures, except for the structure, construction and acceptance of membrane structures other than open and closed and inflatable membrane structures.

3. When using this procedure in reference to the construction membrane structure specified in this regulation, in addition to the provisions of the full feasibility specification, procedures or standards. For membranes, fittings, etc. specified in this regulation, the relevant regulations shall be tested.

4. When designing the membrane structure, it must be calculated and analyzed according to the design conditions. It is strictly forbidden to blindly apply the design or calculation results of other membrane structures.

5. The design, construction and acceptance of the membrane structure shall be in accordance with the relevant national standards in addition to the implementation of this regulation.

6. These specifications are intended for use as a general guideline for designers. A certified construction specifier should be consulted to ensure Project specifications are compliant with local, regional, and national building codes and ordinances.

Terminology

Anchor Bolts – Threaded bolts used to fasten structural members to masonry. Anchor bolts can be in the form of “J” bolts or simply a threaded rod. If a threaded rod is used, there will typically be a nut and a washer secured to the imbed section of the bolt to help resist the possibilities of the bolt being pulled from the concrete.

Anisotropy – The feature of fabric wherein the physical properties and behavior are not the same in all directions.

Anticlastic – A surface with positive (Gaussian) curvature in one principal direction and negative (Gaussian) curvature in the other. A saddle shaped surface (potato chip).

Base Fabric – The uncoated fabric, also known as greige goods.

Bias – Oriented at 45-degrees to the warp and fill directions of the fabric.

Biaxial – Taken along two concurrent orthogonal directions, usually principal directions.

Boss Plate – Doughnut-shaped plate attached to a cable ear plate to reinforce the pinhole and allow a thinner plate.

Butt Seam – Seam created when the two pieces being joined are butted together and joined with a strip twice the width of the seam.

Cable Cuff – Edge treatment in which the fabric is folded over on itself to form a pocket in which a catenary cable can be installed.

Cable Fitting – Device attached to the end of a cable to allow a connection to another member. Fittings can be swaged, speltered or compression type.

Catenary – The curve theoretically formed by a perfectly flexible, uniformly dense, inextensible “cable” suspended from each of two end points. In fabric structures experience, this shape is probably not ever truly developed, but is commonly used to describe the shape developed at the boundary of a uniformly stressed fabric structure attached to a cable which is restrained only at its end points.

Catenary Cable – Steel cables that run through the pockets on the perimeter of a tension structure fabric. The shape of the cable follows that of the pocket, which is typically curved with a ratio of 1:10. The length of the cable is to be determined from by the engineer supplying the fabric patterning. The thickness of the cable is to be determined by the engineer who is calculating the reaction loads at the cable ends.

Catenary Edge – Method of securing the edge of a panel with a cable tensioned between two fixed points.

Catenary Pocket (AKA “Banana Pocket”) – This is the pocket that is placed at the perimeter of the fabric cover to secure the catenary cable. The pocket has a curve with a ratio that is defined by the fabric patterning, but is typically close to a 1:10 ratio. This means for every 10 feet of length, there will be about a foot of bend to it. Due to the curvature of the shape, the pocket is typically fabricated by sealing together two halves of the pocket together with an overlap of 1” to 2” at the outside edge of the pocket.

Clevis – Device used with a cable stud end or a threaded rod to form a pinned connection that is somewhat adjustable.

Coating – A material applied to a fabric for waterproofing and protection of the fabric yarns.

Coating Adhesion – Strength of the bond between the substrate of a fabric and the coating.

Compensation – The operation of shop fabricating a fabric structure or pieces of the structure smaller in the unstressed condition than the actual installed size, to account for the stretch at pre-stress level.

Crimp – The extent of deformation normal to the plane of the fabric that the fill and warp yarns undergo as they are woven together.

Detension – Relieve the tension or stress in a membrane.

Elongation – The change in lengths of a material sample; normally this is associated with some load or force acting on the sample. In fabric, this elongation does not normally refer to true strain of the fiber elements as in the classical sense; but, rather, normally refers to the “apparent” strain resulting from a straightening out of the crimped yarns in the fabric matrix.

Equilibrium Shape – The configuration that a tensioned fabric surface assumes when boundary conditions, pre-stress level, and pre-stress distribution are defined.

Fabric – A woven or laid cloth made of yarns.

Fabric Clamp – Device for clamping the edge of a fabric panel, usually a bar or channel shape and made of aluminum or steel.

Fiber – The basic thread of the material from which the yarns and fabrics are made.

Fill Yarns – The shorter yarns of a fabric, which usually run at right angles to the warp yarns. Also known as weft yarns.

Flutter – Excessive, uncontrolled movement, usually caused by the interaction between the structure and wind. This occurs when the fabric lacks sufficient pre-stress.

Footing – The large concrete anchoring structure that holds the tension structure securely to the ground. The top of the footing is typically flush with the ground level. The footing is comprised of a matrix of steel rebar that is referred to as a cage. The concrete is poured into the hole in the ground that holds the cage. The anchor bolts get placed into the top of the footing at their precise location as indicated in the shop drawings. A certified engineer must calculate the size of the footings. The size of the footing must contain enough weight to hold down the tension structure for the wind loads in the area.

Form Finding (AKA “Form Generation”) – The process of determining the equilibrium shape of a fabric structure.

Greige Goods – Uncoated fabric. Also known as the base fabric.

Guy Cable – This steel cable is used to support the structural integrity of the steel frame. It may be attached at the ends of the steel struts (or “arms”) to hold them together and resist them from movement relative to each other. Unlike catenary cables, the lengths are calculated by a straight point-to-point dimension. The engineer will need to determine the thickness by calculating the maximum stress on the cable.

HDPE – High Density Polyethylene (HDPE) fabric is an extra heavy duty woven mesh fabric that blocks up to 95% of harmful UV rays. This superior Fire Rated Knitted shade fabric is designed for use in modular shade structures and shade sails.

Hysteresis – The failure of fabric to return to its original geometry after the strain-inducing force has been removed.

Keder – Brand name for the solid PVC cord used at a “rope edge”. Rope edges provide strength and a surface to evenly distribute fabric tension forces.

Lap Seam – Seam created when the two pieces being joined are overlapped by the width of the seam.

Light Transmission – A measure of the portion of light striking a fabric surface that passes through the fabric and into the space to provide daylighting.

Mast – The principal upright in a tension structure.

Membrane – The fabric panels used in tension structures.

Membrane Plate – Metal plates attached to the membrane corners used for securing the membrane to the frame.

Modulus of Elasticity – The ratio of the change in stress to the change in strain. Usually defined as a force per unit width of a membrane material.

Node Points – Intersection points of the elements used to define the fabric shape in the structural analysis; these are normally given in terms of a three-dimensional coordinate system.

Patterning – The process of defining two-dimensional pieces of fabric, which can be spiced together to form a desired three-dimensional shape. M-Panel is an add on tool for AutoCAD that has the ability to assist in the process of patterning.

Poisson’s Ratio – The ratio of lateral strain to longitudinal strain; may take a wide range of values due to the deformation characteristics of a woven material.

pre-stress – The stress state that exists in a fabric structure when it is not acted upon by service loads; usually induced by the boundary conditions of the fabric membrane.

PTFE – “Polytetrafluoroethylene”, commonly known by its trademark name Teflon™. This coating is applied to a fiberglass scrim to produce a high strength tension structure fabric membrane with a life expectancy of thirty plus years. PTFE may also be expanded and woven into a fabric that can be coated with a fluoropolymer to create a high strength architectural fabric.

PVC – “Polyvinyl chloride”, properly mixed with plasticizers for flexibility and applied to a polyester scrim makes for a high strength and popular tension structure fabric membrane. The life expectancy and cost are proportionally lower than PTFE.

Radius of Curvature – The inverse of the magnitude of (Gaussian) curvature at a location on a membrane surface. The magnitude is typically considered in two principal directions. The orientation of the principal directions and their magnitude may vary continuously over the surface.

Rebar Cage – A reinforcing matrix of steel rods used to strengthen concrete.

Reinforcement – An additional layer of fabric placed in an area of high stress to protect the main fabric.

Roll Goods – Edge treatment in which the edge of the fabric is folded over on itself and a rope or cord is incorporated in the fold to increase the strength of the clamped fabric.

Sectionalizing – Method of field joining large fabric panels utilizing clamping hardware.

Sleeve – A tube of fabric, which loosely contains a structural element such as a cable, rod, etc.

Spelter – Type of cable fitting in which the strands of the cable are opened inside the fitting and molten lead is poured into the fitting to secure the cable.

Stay Cable – A steel cable that is used to stabilize the mast in response to the forces created by wind loads. The stay cables are used to resist movement of the structure relative to the earth. One end of the cable will typically connect to the end of the steel frame near the fabric connection. The other end will terminate to a sturdy section of the mast or a footing in the ground.

Swage – Type of cable fitting in which a sleeve fits over the outside of the cable and the sleeve is compressed around the cable to form a tight fit.

Synclastic – A surface with positive (Gaussian) curvature in both principal directions. A bubble shaped surface.

Thimble – Device used in a simple cable loop end to secure the cable and bear against the pin. Thimbles are usually used with shackles.

Top Finish (AKA “Topping”) – An additional coating sometimes used on fabric for greater protection against UV degradation or for ease of cleaning purposes (i.e. Ferrari’s PVDF named “T2®”; or Dupont’s PVF named “Tedlar®”).

Turnbuckle – Threaded device used with cables or rods to allow adjustment.

Ultraviolet (UV) Degradation – The deterioration of a fabric under long-term exposure to sunlight. Using a top finish on the fabric will help prevent the UV degradation.

Uniaxial – Taken along one direction, usually a principal direction.

Warp Yarn – The long straight yarns in the long direction of a piece of fabric.

Weaving – The process of making a fabric from yarns passing alternately over and under each other.

Weft Yarn – The shorter yarns of a fabric, which usually run at right angles to the warp yarns. Also called the fill yarns.

Weldment – Connection component, usually steel, for the attachment of cables and/or fabric. If may be free-floating or connected to other membranes.

Wicking – The conveying of liquid by capillary action along and through the yarns of the base fabric.

Wire Rope Clip – U-shaped bolt with a special insert, specifically designed to clamp a wire rope to itself when forming a loop end for temporary cables.

Wrinkles – Furrows or ridges on the normally smooth surface of a fabric structure, which are indicative of extreme differences between the principal stresses typically resulting from a lower stress perpendicular to the furrow.

Yarn – A number of fibers grouped together to make a thicker strand for weaving. They may be twisted together or parallel to each other.